Mohala oa selemo le selemo oa tlhahiso ea lithane tse 30,000 tsa manyolo a manyolo ke ho fetolela mefuta eohle ea litšila tsa tlhaho hore e be manyolo a tlhaho ka mekhoa e fapaneng.Lifeme tsa manyolo a bioorganic ha li khone feela ho fetola manyolo a likhoho le litšila hore e be letlotlo, ho hlahisa melemo ea moruo, empa hape ho fokotsa tšilafalo ea tikoloho le ho hlahisa melemo ea tikoloho.Sebopeho sa likaroloana e ka ba cylindrical kapa spherical, eo ho leng bonolo ho e tsamaisa le ho e sebelisa.Sesebelisoa se ka khethoa ho latela litlhoko tsa hau tsa nnete.

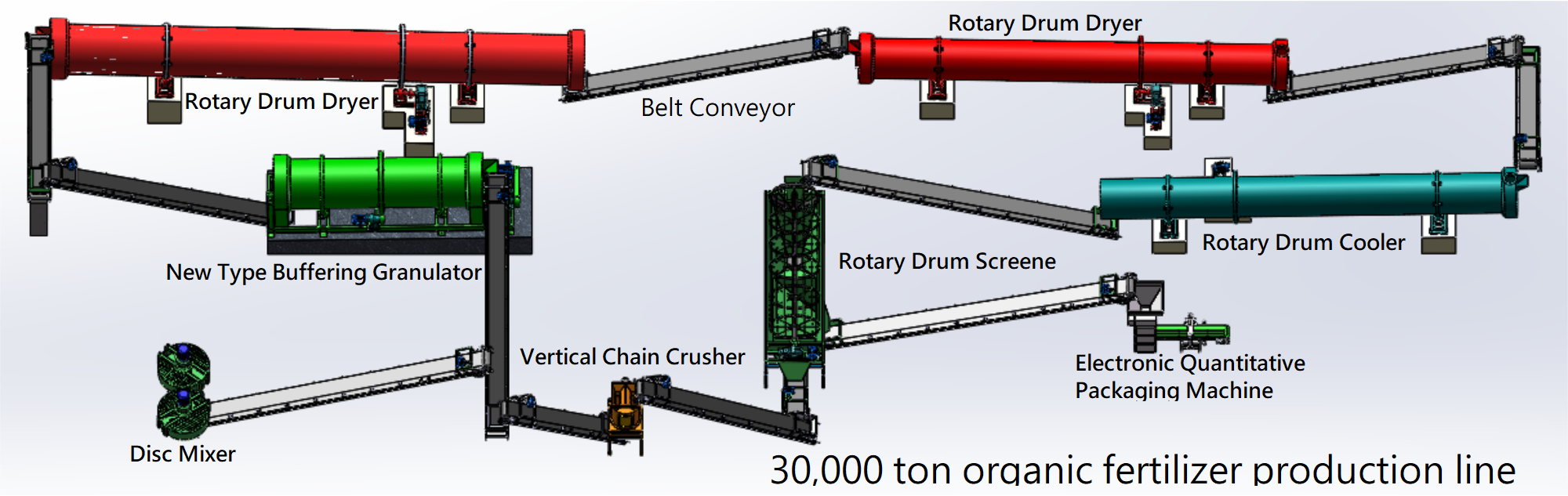

Re fana ka moralo oa ts'ebetso le ho etsa mohala o mocha oa tlhahiso ea buffer granulation bakeng sa manyolo a tlhaho.Lisebelisoa tsa mohala oa tlhahiso haholo-holo li kenyelletsa hopper le feeder, mochini o mocha oa granulation ea buffer, se omisitsoeng, mochini oa sieve oa rolara, seketsoana sa bakete, conveyor lebanta, mochini o pakang le lisebelisoa tse ling tse thusang.

Manyolo a tlhaho a ka etsoa ka masalla a methane, litšila tsa temo, moiteli oa liphoofolo le likhoho le litšila tsa masepala.Litšila tsena tsa tlhaho li hloka ho sebetsoa pele li fetoloa menontsha ea khoebo ea boleng ba khoebo e rekisoang.Letsete la ho fetola litšila hore e be leruo ke la bohlokoa ka ho feletseng.

Lisebelisoa tse tala tsa manyolo a tlhaho li na le lisebelisoa tse ngata, tse arotsoeng haholo ka lihlopha tse latelang.Lisebelisoa tse fapaneng li ka kopanngoa le lisebelisoa tse fapaneng tsa tlhahiso:

1. Mantle a liphoofolo: joalo ka likhoho, likolobe, matata, likhomo, linku, lipere, mebutla, joalo-joalo, masalla a liphoofolo tse kang tlhapi, lijo-thollo tsa masapo, masiba, boea, moiteli oa silika, matamo a biogas, joalo-joalo.

2. Litšila tsa temo: joang ba lijalo, rattan, lijo tsa soybean, rapeseed meal, cottonseed meal, silk melon meal, yeast powder, masalla a mushroom, joalo-joalo.

3. Litšila tsa indasteri: slurry ea veine, masala a asene, masala a cassava, seretse se hloekisang, masala a meriana, slag ea furfural, joalo-joalo.

4. Seretse sa 'masepala: seretse sa noka, seretse, seretse sa foro, seretse sa leoatle, seretse sa letša, humic acid, turf, lignite, sludge, fly ash, joalo-joalo.

5. Lithōle tsa ntlo: litšila tsa kichineng, joalo-joalo.

6. Diction or extract: tlhapi ea leoatleng, tlhapi ea tlhapi, joalo-joalo.

1. Semi-wet material crusher e sebelisoa ho etsa hore e ikamahanye le mongobo oa thepa e tala.

2. Mochini oa ho roala likaroloana o etsa hore boholo ba likaroloana tsa spherical li tšoane, bokaholimo bo boreleli, 'me matla a phahame.E loketse ho hokahana le li-granulator tse fapaneng.

3. Mohala oohle oa tlhahiso o kopantsoe ke conveyor ea lebanta le lisebelisoa tse ling tse tšehetsang.

4. Sebopeho sa Compact, ts'ebetso e tsitsitseng, ts'ebetso e bonolo le tlhokomelo.

5. Sesebelisoa se ka khethoa ho ea ka litlhoko tsa hau tsa sebele.

Ts'ebetso ena e kenyelletsa lisebelisoa tsa ho belisa, mixer, granulation machine, dryer, cooler, roller sieve machine, silo, mochini oa ho paka o ikemetseng ka botlalo, crusher e otlolohileng, conveyor lebanta, joalo-joalo. ho belisoa → ho kopanya metsoako (ho kopanya le lintho tse ling tsa tlhaho-inorganic, NPK≥4%, lintho tse phelang ≥30%) → granulation → sephutheloana.Tlhokomeliso: mohala ona oa tlhahiso ke oa litšupiso feela.

1. Drum dumper

Mokhoa oa ho belisa o bolisa ka botlalo litšila tse phelang hore li belise le ho butsoa.Li-plug tse fapaneng tse kang li-dumpers tse tsamaeang, li-dumper tse peli-helix, li-plug tse grooved, li-dumper tsa hydraulic groove le li-dumper tse lateloang tse hlahisoang ke k'hamphani ea rona li ka khethoa ho latela thepa ea sebele ea composting, libaka le lihlahisoa.

2. Mochine o senyang

Thepa e tala e lomositsoeng e kena ka har'a grinder ea ketane e otlolohileng, e ka pshatlang lisebelisoa tse tala ka metsi a ka tlase ho 30%.Boholo ba likaroloana bo ka fihlela litaelo tsa 20-30, tse finyellang litlhoko tsa granulation.

3. Motsoako o otlolohileng

Ka mor'a ho pshatla, eketsa lisebelisoa tse thusang ho ea ka foromo ebe u kopanya ka ho lekana ka blender.Motsoako o otlolohileng o na le likhetho tse peli: motsoako oa uniaxial le motsoako oa li-axis tse peli.

4. Granulator e ncha ea manyolo a manyolo

Sekhahla sa granulation se tšoanelehang sa mochini se ka holimo ho 90%, se loketseng mefuta e fapaneng ea liforomo tse fapaneng.Matla a hatellang a likaroloana a phahame ho feta a disk granulation le drum granulation, 'me sekhahla se seholo sa spherical se ka tlase ho 15%.

5. Ea lahlang lerako

Mochini o pota-potileng o ka lokisa le ho khabisa likaroloana tsa granulation ka mor'a granulation.Ka mor'a ho hlahisa granulation kapa disk granulation process, ka mor'a ho lahlela ho pota-pota, likaroloana tsa manyolo li ka lekana ka boholo, li pota-potile, li khanyang ebile li boreleli holim'a metsi, matla a maholo a likaroloana, 'me lihlahisoa tse chitja tsa manyolo li ka holimo ho 98%.

6. E omme ebile e pholile

The rolara dryer e tsoela pele ho pompa mohloli oa mocheso ka setofong sa moea o chesang sebakeng sa nko ho ea mohatleng oa enjene ka fene e kentsoeng mohatleng oa mochini, e le hore thepa e kopane ka botlalo le moea o chesang le ho fokotsa metsi. dikahare tsa dikarolwana.

Roller cooler e pholisa likaroloana ka mocheso o itseng ka mor'a ho omisa, 'me e fokotsa metsi a likaroloana hape ha e ntse e fokotsa mocheso oa karoloana.

7. Sieve ea rolara

E sebelisoa haholo-holo bakeng sa ho arola lihlahisoa tse feliloeng ho thepa e tsosolositsoeng.Ka mor'a ho sieving, likaroloana tse tšoanelehang li kenngoa ka mochine oa ho roala, 'me likaroloana tse sa tšoaneleheng li kenngoa ka har'a mochine o otlolohileng oa ketane ho khutlisetsa regrainate, kahoo ho finyella lihlahisoa tsa lihlahisoa le lihlopha tse tšoanang tsa lihlahisoa tse felileng.Mochine o amohela skrine e kopantsoeng, eo ho leng bonolo ho e hlokomela le ho e nkela sebaka.Sebopeho sa eona se bonolo, se sebetsa habonolo ebile se boreleli.E tsitsitse, ke sesebelisoa sa bohlokoahali tlhahisong ea manyolo.

8. Mochini oa ho paka:

Ho roala ha likaroloana tse tšoanelehang ka mochine oa ho roala rotary ha ho etse feela likaroloana tse ntle, empa hape ho ntlafatsa ho thatafala ha likaroloana.Mochini oa ho roala oa rotary o sebelisa theknoloji e khethehileng ea ho fafatsa thepa ea mokelikeli le theknoloji ea ho fafatsa phofo e tiileng ho thibela ka nepo ho thibela likaroloana tsa manyolo.

9. Mochini oa ho paka o ikemetseng:

Ka mor'a hore likaroloana li koahetsoe, li kenngoa ka mochine oa ho paka.Mochine oa ho paka o na le tekanyo e phahameng ea ho iketsetsa, ho kopanya boima, suture, ho paka le lipalangoang, tse hlokomelang liphutheloana tse potlakileng tsa palo le ho etsa hore mokhoa oa ho paka o sebetse hantle le o nepahetseng.

10. Conveyor ea lebanta:

Conveyor e bapala karolo ea bohlokoa ts'ebetsong ea tlhahiso, hobane e hokahanya likarolo tse fapaneng tsa mohala oohle oa tlhahiso.Moleng ona oa tlhahiso ea manyolo a kopantsoeng, re khetha ho u fa lebanta la conveyor.Ha ho bapisoa le mefuta e meng ea li-conveyors, li-conveyors tsa mabanta li na le tšireletso e kholo, e leng se etsang hore mokhoa oa hau oa tlhahiso o sebetse hantle le ho boloka chelete.