Re na le boiphihlelo bo felletseng ba mohala oa tlhahiso ea granulation ea dryless extrusion.Ha re tsepamise maikutlo feela ho sehokelo se seng le se seng sa ts'ebetso ea tlhahiso, empa hape re lula re utloisisa lintlha tsa ts'ebetso ea mohala o mong le o mong oa tlhahiso mme re fihlelle ho hokahanya ka katleho.Ts'ebetso e felletseng ea tlhahiso ke o mong oa melemo ea mantlha ea tšebelisano ea hau le YiZheng Heavy Machinery Co., Ltd Re fana ka litharollo tsa mela ea tlhahiso e hlophisitsoeng ho latela litlhoko tsa 'nete tsa bareki.

No-drying Extrusion Compound Fertilizer Production Linee ka hlahisa manyolo a kopaneng a phahameng, a mahareng le a tlase bakeng sa lijalo tse fapaneng.Mohala oa tlhahiso ha o hloke ho omella, ka matsete a manyenyane le tšebeliso e tlaase ea matla.

Rolara ntle le ho omisa extruding granulation e ka etsoa ka likaroloana tsa libopeho le boholo bo fapaneng mme e ka fetisoa ho hlahisa boholo bo fapaneng.

Ka kakaretso, manyolo a kopantsoeng a na le bonyane limatlafatsi tse peli kapa tse tharo (naetrojene, phosphorus, potasiamo).E na le litšobotsi tse nang le limatlafatsi tse ngata le litla-morao tse fokolang.Manyolo a motsoako o phetha karolo ea bohlokoa ho nontšeng ho leka-lekaneng.Ho ke ke ha feela ho ntlafatsa manyolo ka katleho, empa hape ho kgothaletsa e tsitsitseng le e phahameng chai ea lijalo.

Lisebelisoa tse tala bakeng sa tlhahiso ea manyolo a kopantsoeng li kenyelletsa urea, ammonium chloride, ammonium sulfate, liquid ammonia, ammonium monophosphate, diammonium phosphate, potasiamo chloride, potassium sulfate, ho kenyelletsa le letsopa le li-filler tse ling.

1) Manyolo a naetrojene: ammonium chloride, ammonium sulfate, ammonium thio, urea, calcium nitrate, joalo-joalo.

2) Manyolo a potasiamo: potassium sulfate, joang le molora, joalo-joalo.

3) Manyolo a Phosphorus: calcium perphosphate, heavy calcium perphosphate, calcium magnesium le phosphate manyolo, phosphate ore phofo, joalo-joalo.

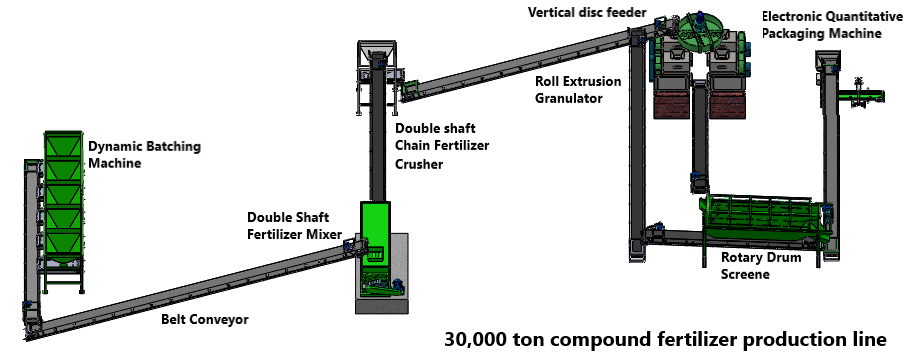

Re fana ka sete e felletseng ea mela ea tlhahiso ea granulation e sa omeletseng e sa hlokeng ho omisoa.Lisebelisoa tsa mohala oa tlhahiso haholo-holo li kenyelletsa mixer le disk feeder, mochini oa granulation oa roller extrusion, mochini oa sieve oa roller, conveyor lebanta, mochini oa ho paka othomathike le lisebelisoa tse ling tse thusang.

Joaloka moetsi ea hloahloa oa lisebelisoa tsa mohala oa tlhahiso ea manyolo, re fa bareki lisebelisoa tsa tlhahiso le tharollo e loketseng ka ho fetisisa bakeng sa litlhoko tse fapaneng tsa tlhahiso ea tlhahiso joalo ka lithane tse 10,000 ka selemo ho isa ho lithane tse 200,000 ka selemo.

1. Mechini ea khatello ea granulation e sebelisoa ntle le ho futhumatsa kapa ho nosetsa lisebelisoa tse tala.

2. E loketse lisebelisoa tse tala tse utloang mocheso, joalo ka ammonium bicarbonate

3. Ha ho hlokahale ho omisa ts'ebetso, ka lichelete tse fokolang le tšebeliso e tlaase ea matla.

4. Ha ho na metsi a litšila, ha ho na khase ea mouoane, ha ho na tšilafalo ea tikoloho.

5. Kabo ea boholo ba likaroloana e tšoana, 'me ha ho na khethollo le agglomeration.

6. Sebopeho sa Compact, theknoloji e tsoetseng pele, ts'ebetso e tsitsitseng le tlhokomelo e bonolo.

7. Ho bonolo ho sebetsa, ho lemohuoa habonolo ho laola, le ho ntlafatsa katleho ea tlhahiso.

8. Ho na le mefuta e mengata ea lisebelisoa tse tala ntle le litlhoko tse khethehileng tsa ts'ebetso.

Granulator e sa omeletseng e kenyelletsa metsoako ea othomathike, li-conveyors tsa mabanta, li-mixer tsa biaxial, li-feeders tsa disc, metjhini ea granulation ea extrusion, li-roller sieve, matlo a polokelo a felileng, mechini ea ho paka ka boiketsetso, jj.

1. Mochini o Matla oa Batching

Mochini o ikatisang oa metsoako o fepa lisebelisoa tse tala ho latela karo-karolelano ea foromo e 'ngoe le e' ngoe, e ka phethelang ts'ebetso ea batching ka ho nepahala le ho sebetsa hantle, e le ho netefatsa boleng ba manyolo.Ka mor'a lisebelisoa, thepa e fetisetsoa ho blender ea double-axis.

2. Motsoako oa Fertilizer oa Shaft habeli

Motsoako oa disc o sebelisa mochini o fokotsang lebili la nale ho khanna lebili, ebe o khanna letsoho le sisinyehang ho potoloha le ho sisinyeha.Ka ho phenyekolla ho tsoelang pele le ho tsosoa ha li-blades ka letsoho la ho kopanya, lisebelisoa tse tala li kopane ka ho feletseng.Thepa e tsoakiloeng e ntšitsoe ho tsoa ho tsoa ka tlase.Disk e amohela poleiti ea polypropylene kapa lesela la tšepe le sa hloekang, leo ho seng bonolo ho khomarela le ho le bonolo ebile le sebetsa.

3. Roller extrusion granulator

Thepa e tsoakiloeng e tala e tsamaisoa ho tloha lebanta conveyor ho disc feeder, e leng evenly romela lintho tse bonahalang tse nne rolara extruder tlas'a phepelo ka hopper.Mochine o pepeta lintho tse bonahalang likotoana ho kamoreng e robehileng tlas'a rolara ka rolara e potolohang e phahameng ea motlakase, ebe e arola likaroloana tse hlokahalang ha molamu oa meno oa phiri o pota-pota habeli.Rolara e entsoe ka lisebelisoa tsa alloy tse ncha tse sa jeng, tse sa senyeheng le tse hananang le tšusumetso.

4. Rotary Drum Screene

Likaroloana tse atolositsoeng tsa granulation li fetisetsoa ho sefahla sa roller ka lebanta, 'me likaroloana tse tlase li phalla ka ntle ho karolo e kholo ea lehlakore ka lesoba la skrine, ebe li fetisetsoa ho disc feeder bakeng sa granulation ea bobeli,' me likaroloana tse tšoanelehang li feptjoa ho tsoa ho kotulo e tlase ebe e isoa sebakeng se felileng.

5. Electronic Quantitative Packaging

Ka hopper, likaroloana tse tšoanelehang li lekanngoa ka bongata, ebe li kenngoa ka mochine o ikemetseng oa ho paka.