Ho nts'etsapele temo e tala, re tlameha ho qala ka ho rarolla bothata ba tšilafalo ea mobu.Mathata a tloaelehileng mobung ke: ho petetsana ha mobu, ho se leka-lekane ha karo-karolelano ea phepo ea liminerale, lintho tse phelang tse fokolang, mobu o sa tebang, acidization ea mobu, letsoai la mobu, tšilafalo ea mobu, joalo-joalo. mobu o hloka ho ntlafatsoa.Ntlafatsa lintho tse phelang mobung, e le hore ho be le li-pellets tse ngata le likarolo tse fokolang tse kotsi mobung.

Re fana ka moralo oa ts'ebetso le ho etsa sete e felletseng ea mela ea tlhahiso ea manyolo a manyolo.Manyolo a tlhaho a ka etsoa ka masalla a methane, litšila tsa temo, moiteli oa liphoofolo le likhoho le litšila tsa masepala.Litšila tsena tsa tlhaho li hloka ho sebetsoa pele li fetoloa menontsha ea khoebo ea boleng ba khoebo e rekisoang.Letsete la ho fetola litšila hore e be leruo ke la bohlokoa ka ho feletseng.

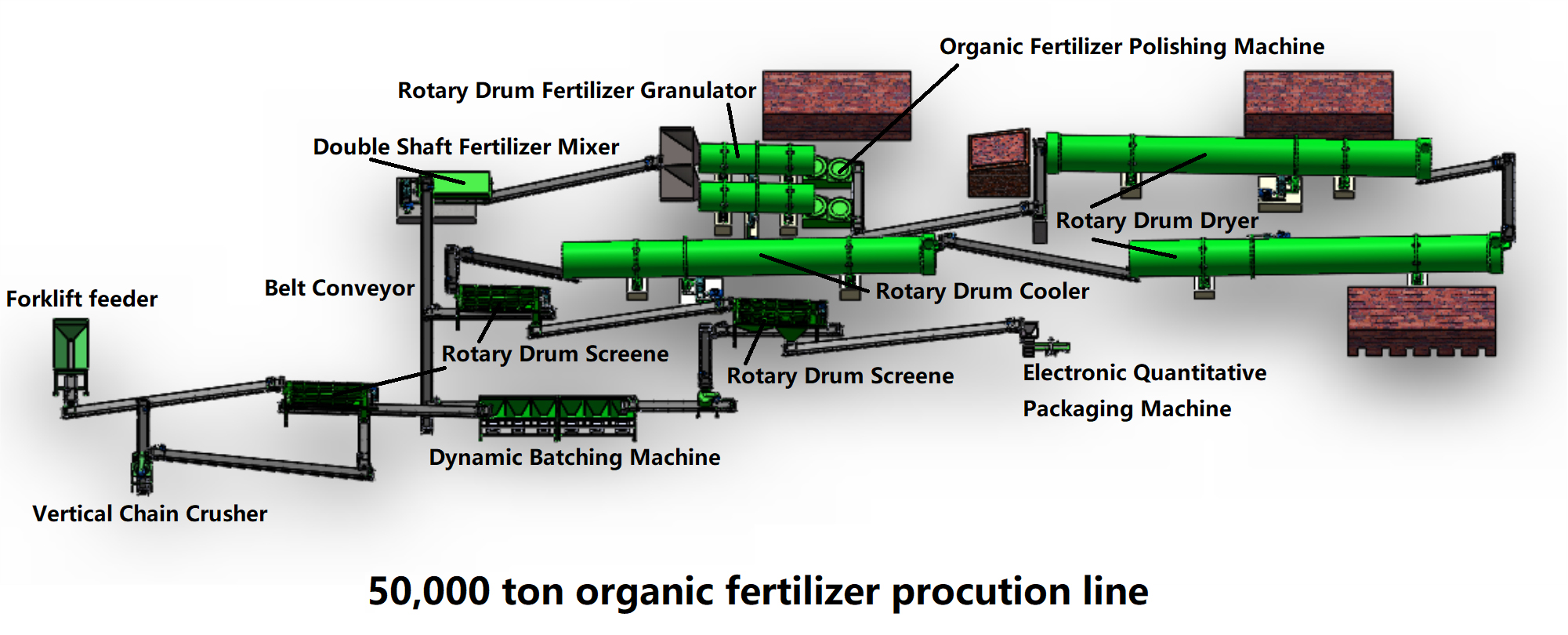

Mohala oa tlhahiso ea manyolo a macha a nang le tlhahiso ea selemo le selemo ea lithane tse 50,000 o sebelisoa haholo tlhahisong ea manyolo a manyolo a nang le litšila tsa temo, manyolo a liphoofolo le likhoho, litšila le litšila tsa litoropo e le lisebelisoa tse tala.Mohala oohle oa tlhahiso o ke ke oa fetolela litšila tse fapaneng tsa manyolo hore e be manyolo a manyolo, empa hape o tlisa melemo e meholo ea tikoloho le moruo.

Lisebelisoa tsa mohala oa tlhahiso ea manyolo a manyolo haholo-holo li kenyelletsa hopper le feeder, drum granulator, dryer, roller sieve mochini, hoist bakete, conveyor lebanta, mochini o pakang le lisebelisoa tse ling tse thusang.

Lisebelisoa tse tala tse sebelisoang haholo

Mohala o mocha oa tlhahiso ea manyolo o ka sebelisoa linthong tse fapaneng tsa manyolo, haholo-holo joang, masalla a joala, masalla a baktheria, masala a oli, moiteli oa liphoofolo le likhoho le lisebelisoa tse ling tseo ho seng bonolo ho li hula.E ka boela ea sebelisoa bakeng sa phekolo ea humic acid le likhoerekhoere tsa likhoerekhoere.

Se latelang ke karohano ea lisebelisoa tse tala meleng ea tlhahiso ea manyolo a manyolo:

1. Litšila tsa temo: joang, masala a linaoa, slag ea k'hothone, bran ea raese, joalo-joalo.

2. Moiteli oa liphoofolo: motsoako oa moiteli oa likhoho le mantle a liphoofolo, joalo ka mahlabelo, litšila tse tsoang limmarakeng tsa litlhapi, likhomo, likolobe, linku, likhoho, matata, likhantsi, moroto oa lipōli le mantle.

3. Litšila tsa indasteri: masala a joala, masala a asene, masala a cassava, masalla a tsoekere, masala a furfural, joalo-joalo.

4. Litšila tsa malapa: litšila tsa lijo, metso le makhasi a meroho, joalo-joalo.

5. Sludge: seretse se tsoang linōkeng, likhoerekhoere, joalo-joalo.

Mohala oa tlhahiso ea manyolo a manyolo o na le dumper, mixer, crusher, granulator, dryer, cooler, mochini oa ho paka, jj.

Mohala o mocha oa tlhahiso ea manyolo a manyolo o na le litšobotsi tsa ts'ebetso e tsitsitseng, ts'ebetso e phahameng, tlhokomelo e bonolo le bophelo bo bolelele ba ts'ebeletso.

1. Mefuta ena e fapa-fapaneng ha e tšoanelehe feela bakeng sa manyolo a manyolo, empa le bakeng sa menontsha ea likokoana-hloko ea likokoana-hloko tse eketsang libaktheria tse sebetsang.

2. Bophara ba manyolo bo ka fetoloa ho latela litlhoko tsa bareki.Mefuta eohle ea li-granulators tsa manyolo tse hlahisoang fekthering ea rona li kenyelletsa: li-granulator tse ncha tsa manyolo, li-disk granulators, li-granulator tse bataletseng tsa hlobo, li-drum granulator, joalo-joalo Khetha li-granulator tse fapaneng ho hlahisa likaroloana tsa libopeho tse fapaneng.

3. E sebelisoa haholo.E ka tšoara lisebelisuoa tse sa tšoaneng tse tala, tse kang litšila tsa liphoofolo, litšila tsa temo, litšila tse belisoang, joalo-joalo. Lisebelisoa tsena tsohle tse tala li ka etsoa ka lihlopha tsa menontsha ea khoebo ea granular.

4. Boiketsetso bo phahameng le ho nepahala ho phahameng.Sistimi ea metsoako le mochini oa ho paka li laoloa ke likhomphutha le ho iketsetsa.

5. Boleng bo phahameng, ts'ebetso e tsitsitseng, ts'ebetso e bonolo, tekanyo e phahameng ea automation le bophelo bo bolelele ba tšebeletso.Re nka tlaleho e felletseng ea boiphihlelo ba basebelisi ha re rala le ho etsa mechini ea manyolo.

Litšebeletso tsa tlatsetso ea boleng:

1. Fektheri ea rona e ka thusa ho fana ka moralo oa motheo oa motheo ka mor'a hore litaelo tsa lisebelisoa tsa bareki li tiisetsoe.

2. Khampani e lumellana ka tieo le litekanyetso tse loketseng tsa tekheniki.

3. Leka ho latela melaoana e amehang ea tlhahlobo ea lisebelisoa.

4. Tlhahlobo e tiileng pele sehlahisoa se tloha fekthering.

1. Mosuela

Mantle a liphoofolo tse ruiloeng le likhoho le lintho tse ling tse tala li kenngoa ka kotloloho sebakeng sa ho belisoa.Ka mor'a ho belisoa le ho tsofala ha bobeli le ho bokellana, monko oa liphoofolo tse ruiloeng le oa likhoho o felisoa.Libaktheria tse halikiloeng li ka eketsoa sethaleng sena ho senya likhoele tse mahoashe tse ho eona e le hore litlhoko tsa boholo ba likaroloana tsa ho sila li ka finyella litlhoko tsa granularity tsa tlhahiso ea granulation.Mocheso oa lihlahisoa tse tala o lokela ho laoloa ka thata nakong ea ho belisoa ho thibela mocheso o feteletseng le ho thibela mosebetsi oa likokoana-hloko le li-enzyme.Mechini e tsamaeang ka maoto le metjhini ea hydraulic flip e sebelisoa haholo ho phethola, ho kopanya le ho potlakisa ho belisoa ha mekotla.

2. Motlakase oa manyolo

The fermented material crushing process e phethelang botsofali ba bobeli le stacking process e ka sebelisoa ke bareki ho khetha semi-wet material crusher, e ikamahanyang le mongobo oa thepa e tala ka mefuta e mengata.

3. Hlohlelletsa

Ka mor'a ho pshatla thepa e tala, eketsa limatlafatsi tse ling kapa lisebelisoa tse ling ho latela mokhoa oa ho etsa motsoako, 'me u sebelise motsoako o otlolohileng kapa o otlolohileng nakong ea ts'ebetso ea ho hlohlelletsa ho hlohlelletsa thepa e tala le ho kopanya ka ho lekana.

4. Ho omisa

Pele ho granulation, haeba mongobo oa thepa e tala o feta 25%, ka mongobo o itseng le boholo ba likaroloana, metsi a lokela ho ba ka tlase ho 25% haeba se omisitsoeng sa drum se sebelisetsoa ho omisa.

5. Granulation

Mochini o mocha oa granule oa manyolo o sebelisoa ho kopanya thepa e tala hore e be libolo ho boloka ts'ebetso ea likokoana-hloko.Sekhahla sa ho phela ha likokoana-hloko tse sebelisang granulator ena ke ho feta 90%.

6. Ho omisa

Mongobo oa likaroloana tsa granulation o ka ba 15% ho isa ho 20%, eo ka kakaretso e fetang sepheo.E hloka mechini e omisang ho nolofatsa lipalangoang le polokelo ea manyolo.

7. Ho pholisa

Sehlahisoa se omisitsoeng se kena ka sehatsetsing ka lebanta la conveyor.Mohatsela o amohela sehlahisoa sa mocheso o pholileng o nang le moea o pholileng ho felisa mocheso o setseng ka ho feletseng, ha o ntse o fokotsa metsi a likaroloana.

8. Sieving

Re fana ka mochini oa sieving oa drum oa boleng bo holimo le o sebetsang hantle ho fihlela sehlopha sa lisebelisoa tse nchafalitsoeng le lihlahisoa tse felileng.Thepa e tsosolositsoeng e khutlisetsoa ho crusher bakeng sa ts'ebetso e tsoelang pele, 'me sehlahisoa se felileng se isoa mochining oa ho roala manyolo kapa ka kotloloho mochining oa ho paka o ikemetseng.

9. Sephutheloana

Sehlahisoa se phethiloeng se kena ka har'a mochini oa ho paka ka lebanta la conveyor.Etsa liphutheloana tse ngata le tse ikemetseng tsa lihlahisoa tse felileng.Mochini oa ho paka o na le mefuta e mengata e fapaneng ea bongata le ho nepahala ho phahameng.E kopantsoe le mochini o rokang oa conveyor o nang le countertop e phahamisitsoeng.Mochine o le mong o sebetsa ka litsela tse ngata ebile o sebetsa hantle.Kopana le litlhoko tsa ho paka le tikoloho ea tšebeliso ea thepa e fapaneng.