Lisebelisoa tse felletseng tsa tlhahiso bakeng sa manyolo a kopaneng

Thepa e felletseng ea tlhahiso ea manyolo a kopantsoeng hangata e kenyelletsa mechini le lisebelisoa tse latelang:

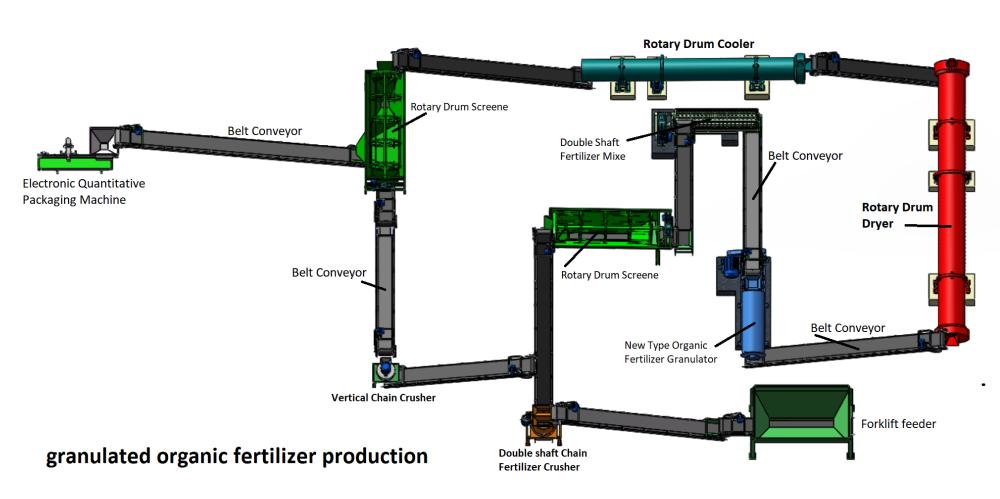

1. Lisebelisoa tsa ho senya: E sebelisetsoa ho pshatla lihlahisoa tse tala ka likaroloana tse nyenyane ho thusa ho kopanya le granulation.Sena se kenyelletsa li-crusher, li-grinders le li-shredders.

2.Lisebelisoa tsa ho kopanya: E sebelisetsoa ho kopanya lisebelisoa tse sa tšoaneng tse tala ho etsa motsoako oa homogeneous.Sena se kenyelletsa li-mixer tse tšekaletseng, li-mixer tse otlolohileng, le li-disk mixer.

Lisebelisoa tsa 3.Granulating: E sebelisetsoa ho fetola lisebelisoa tse tsoakiloeng ka li-granules kapa pellets.Sena se kenyelletsa li-granulator tsa meropa ea rotary, li-granulator tsa "double roller extrusion", le li-pan granulator.

Lisebelisoa tsa 4.Drying: E sebelisetsoa ho fokotsa mongobo oa li-granules ka mor'a granulation, ho etsa hore ho be bonolo ho sebetsana le ho boloka.Sena se kenyelletsa li-dryer tsa rotary, li-dryer tse nang le metsi, le li omisa mabanta.

Lisebelisoa tsa 5.Ho pholile: E sebelisetsoa ho pholile li-granules ka mor'a ho omisa ho thibela ho khomarela kapa ho senya.Sena se kenyelletsa li-cooler tsa rotary, li-cooler tse nang le metsi, le li-counter-flow coolers.

Lisebelisoa tsa 6.Screening: E sebelisetsoa ho tlosa li-granules leha e le life tse kholo kapa tse tlaase ho sehlahisoa sa ho qetela, ho netefatsa hore sehlahisoa ke sa boholo bo tsitsitseng le boleng.Sena se kenyelletsa li-skrini tse thothomelang le li-skrini tsa rotary.

7. Lisebelisoa tsa ho roala: E sebelisetsoa ho eketsa lesela le sireletsang ho li-granules, tse ka ntlafatsang ho hanyetsa ha tsona ho mongobo, li-caking le mefuta e meng ea ho senyeha.Sena se kenyelletsa liphaephe tsa meropa le liphahlo tse nang le metsi.

8.Thepa ea ho paka: E sebelisetsoa ho paka sehlahisoa sa ho qetela ka mekotleng kapa lijaneng bakeng sa ho boloka le ho aba.Sena se kenyelletsa mechini ea othomathike ea mekotla, metjhini e tlatsang, le li-palletizer.

Thepa e felletseng ea tlhahiso ea manyolo a kopantsoeng e ka hlophisoa hore e lumellane le bokhoni ba tlhahiso le litlhoko tse fapaneng, ho latela litlhoko tse ikhethileng tsa mosebelisi.Thepa e etselitsoe ho hlahisa menontsha ea boleng bo holimo, e leka-lekaneng e fanang ka litekanyetso tse tsitsitseng tsa limatlafatsi bakeng sa lijalo, ho thusa ho eketsa chai le ho ntlafatsa bophelo bo botle ba mobu.