Ts'ebetso e felletseng le e fapaneng ea tlhahiso ea li-disk granulation ke o mong oa melemo ea mantlha ea Henan Zheng Heavy Industries.E ka fana ka tharollo e feletseng le e ka tšeptjoang ea line ea tlhahiso ho latela litlhoko tsa sebele tsa bareki.

Re na le boiphihlelo moralong le ts'ebeletsong ea mehala e fapaneng ea tlhahiso ea manyolo.Ha re tsepamise maikutlo feela ho sehokelo se seng le se seng sa ts'ebetso ea tlhahiso, empa hape re lula re utloisisa lintlha tsa ts'ebetso e 'ngoe le e' ngoe moleng oohle oa tlhahiso mme re fihlelle ka katleho ho hokahanya.

Mohala oa tlhahiso ea disk granulator o sebelisoa haholo-holo ho hlahisa manyolo a manyolo.Manyolo a tlhaho a ka etsoa ka moiteli oa liphoofolo le likhoho, litšila tsa temo le litšila tse tiileng tsa masepala.Litšila tsena tsa tlhaho li hloka ho sebetsoa pele li fetoloa menontsha ea khoebo ea boleng ba khoebo e rekisoang.Letsete la ho fetola litšila hore e be leruo ke la bohlokoa ka ho feletseng.

Mohala oa tlhahiso ea manyolo a nang le granulated organic o loketse bakeng sa:

- ►Ho etsa manyolo a tlhaho a bolokoe ba nama ea khomo

- ►Tlhahiso ea manyolo a manyolo a likolobe

- ►Ho etsoa ha manyolo a tlhaho a likhoho le matata

- ►Ho etsa manyolo ka litlama tsa linku

- ►Ho etsoa ha manyolo a tlhaho a litšila tsa litoropo

1. moiteli oa liphoofolo: moiteli oa likhoho, moiteli oa likolobe, moiteli oa linku, moiteli oa khomo, moiteli oa lipere, manyolo a mebutlanyana, joalo-joalo.

2. litšila tsa indasteri: morara, slag ea asene, masala a cassava, masala a tsoekere, litšila tsa biogas, masala a boea, joalo-joalo.

3. Litšila tsa temo: joang ba lijalo, phofo ea soya, phofo ea cottonseed, joalo-joalo.

4. Litšila tsa ka tlung: lithōle tsa kichineng

5. sludge: sludge ea litoropong, seretse sa nōka, seretse se hloekisang, joalo-joalo.

Mohala oa tlhahiso ea li-disk granulation o tsoetse pele, o sebetsa hantle ebile o sebetsa, sebopeho sa lisebelisoa se kopane, automation e phahame, 'me ts'ebetso e bonolo, e loketseng tlhahiso e ngata ea manyolo a manyolo.

1. Lisebelisoa tse thibelang ho bola le tse sa senyeheng li sebelisoa lisebelisoa tsohle tsa mohala oa tlhahiso.Ha ho mesi e meraro ea litšila, ho boloka matla le ho sireletsa tikoloho.E sebetsa ka mokhoa o tsitsitseng 'me ho bonolo ho e hlokomela.

2. Matla a tlhahiso a ka fetoloa ho latela litlhoko tsa bareki.Sebopeho sa mohala oohle oa tlhahiso o kopane, oa saense ebile oa utloahala, 'me theknoloji e tsoetse pele.

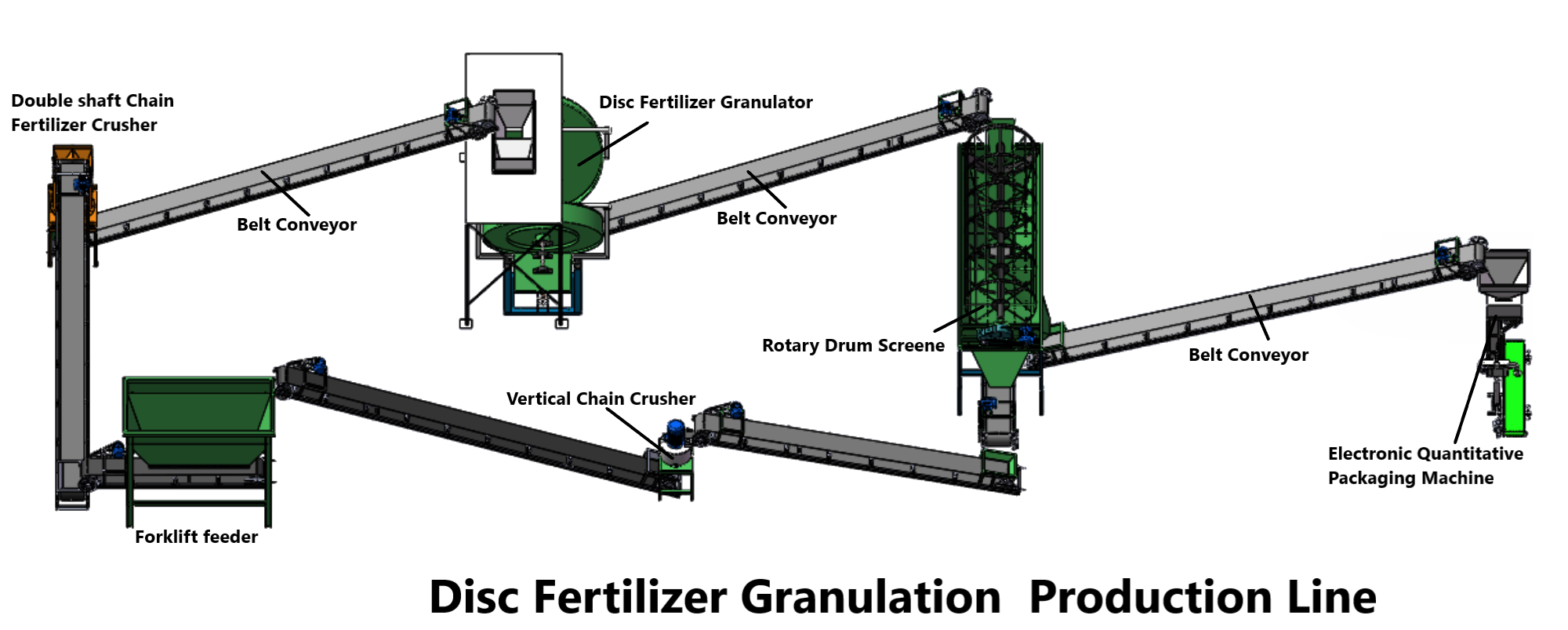

Lisebelisoa tsa mochini oa tlhahiso ea Disk granulation li kenyelletsa polokelo ea lisebelisoa → blender (sirring) → mochini oa granulation oa disk (granulator) → mochini oa sieve oa roller (o khethollang lihlahisoa tse maemong a tlase ho tsoa lihlahisoa tse felileng) → mochini o phuthelang o otlolohileng (ho phuthela) → conveyor lebanta ( ho hokela lits'ebetsong tse fapaneng).

Tlhokomeliso: mohala ona oa tlhahiso ke oa litšupiso feela.

Phallo ea ts'ebetso ea mohala oa tlhahiso ea disk granulation hangata e ka aroloa ka:

1. Ts'ebetso ea lisebelisoa tse tala

Karolelano e tiileng ea thepa e tala e ka netefatsa katleho e phahameng ea manyolo.Lisebelisoa tse tala li kenyelletsa mantle a liphoofolo, litholoana tse bolileng, likhapetla, meroho e tala, manyolo a tala, manyolo a leoatle, manyolo a polasi, litšila tse tharo, likokoana-hloko le litšila tse ling tsa manyolo.

2. Mokhoa oa ho kopanya thepa e tala

Lisebelisoa tsohle tse tala li kopane 'me li hlohlelletsoa ka mokhoa o ts'oanang ka blender.

3. Ts'ebetso e robehileng

The vertical chain crusher e pshatla likotoana tse kholo tsa thepa likotoana tse nyane tse ka fihlelang litlhoko tsa granulation.Ebe lebanta la conveyor le romella thepa ka har'a mochini oa granulation oa disk.

4. Mokhoa oa granulation

Sekhahla sa disk sa mochini oa granulation disk se nka sebopeho sa arc, 'me sekhahla sa ho etsa bolo se ka fihla ho feta 93%.Ka mor'a hore boitsebiso bo kene ka poleiti ea granulation, ka ho potoloha ho tsoelang pele ha granulation disk le sesebelisoa sa spray, thepa e kopantsoe ka ho lekana ho hlahisa likaroloana tse nang le sebōpeho se ts'oanang le sebopeho se setle.

5. Mokhoa oa ho hlahloba

Thepa e pholisitsoeng e isoa mochineng oa sieve oa rolara bakeng sa ho hlahlojoa.Lihlahisoa tse tšoanelehang li ka kena ka tlung ea polokelo e phethiloeng ka lebanta la conveyor, hape li ka kenngoa ka ho toba.Likaroloana tse sa tšoaneleheng li tla khutlela ho regrainate.

6. Ts'ebetso ea ho paka

Packaging ke mokhoa oa ho qetela oa tlhahiso ea manyolo a manyolo.Sehlahisoa se felileng se phuthetsoe ka mochini oa ho paka o ikemetseng ka botlalo.Tekanyo e phahameng ea boits'oaro le ts'ebetso e phahameng ha e fihlelle feela boima bo nepahetseng, empa hape e phethela ts'ebetso ea ho qetela ka bokhabane.Basebelisi ba ka laola lebelo la phepelo mme ba beha li-parameter tsa lebelo ho latela litlhoko tsa 'nete.