Thepa ea tlhahiso ea li-disc granulator

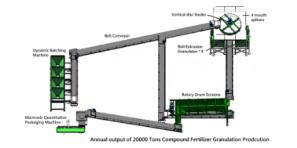

Thepa ea tlhahiso ea li-disc granulator ke mofuta oa lisebelisoa tse sebelisetsoang ho bokella lisebelisoa tse fapaneng ho li-granules.Lisebelisoa tsa mantlha tse ka kenyelletsoang setsing sena ke:

Lisebelisoa tsa 1.Feeding: Thepa ena e sebelisetsoa ho fana ka lisebelisoa tse tala ka har'a granulator ea disc.E ka kenyelletsa conveyor kapa hopper ea ho fepa.

2.Disc Granulator: Ena ke thepa ea mantlha ea mohala oa tlhahiso.Granulator ea disk e na le diski e potolohang, scraper, le sesebelisoa sa ho fafatsa.Lisebelisoa tse tala li kenngoa ka har'a disc, e potolohang ho etsa li-granules.The scraper e thusa ho tsamaisa lisebelisoa ho pota-pota disc, ha sesebelisoa sa ho fafatsa se eketsa mongobo ho lisebelisoa ho li thusa ho khomarela.

3.Drying Equipment: Sesebelisoa sena se sebelisetsoa ho omisa li-granules tsa manyolo a manyolo ho mongobo o loketseng ho boloka le ho tsamaisa.Lisebelisoa tsa ho omisa li ka kenyelletsa mochini o omisang rotary kapa mochini o omisang bethe oa mokelikeli.

4.Lisebelisoa tsa ho Pholisa: Sesebelisoa sena se sebelisetsoa ho pholisa li-granules tse omisitsoeng tsa manyolo a manyolo le ho li lokisetsa ho paka.Thepa ea ho futhumatsa e ka kenyelletsa pholile ea rotary kapa counterflow cooler.

5.Screening Equipment: Sesebelisoa sena se sebelisetsoa ho lekola le ho beha likhalase tsa manyolo a manyolo ho latela boholo ba likaroloana.Thepa ea ho hlahloba e ka kenyelletsa skrine e sisinyehang kapa sekirini sa rotary.

Lisebelisoa tsa 6. Coating: Sesebelisoa sena se sebelisetsoa ho roala li-granules tsa manyolo a manyolo ka lesela le tšesaane la lintho tse sireletsang, tse ka thusang ho thibela tahlehelo ea mongobo le ho ntlafatsa ho monya limatlafatsi.Lisebelisoa tsa ho roala li ka kenyelletsa mochine oa ho roala oa rotary kapa mochine oa ho roala moropa.

7.Packing Equipment: Thepa ena e sebelisetsoa ho paka li-granules tsa manyolo ka mekotleng kapa lijaneng tse ling.Thepa ea ho paka e ka kenyelletsa mochini oa mokotla kapa mochini oa ho paka ka bongata.

8.Conveyor System: Sesebelisoa sena se sebelisetsoa ho tsamaisa lisebelisoa tsa manyolo a manyolo le lihlahisoa tse felileng lipakeng tsa lisebelisoa tse fapaneng tsa ho sebetsa.

9.Control System: Thepa ena e sebelisetsoa ho laola ts'ebetso ea ts'ebetso eohle ea tlhahiso le ho netefatsa boleng ba lihlahisoa tsa manyolo a manyolo.

Ke habohlokoa ho hlokomela hore lisebelisoa tse khethehileng tse hlokahalang li ka fapana ho itšetlehile ka mofuta oa manyolo a tlhaho a hlahisoang, hammoho le litlhoko tse khethehileng tsa ts'ebetso ea tlhahiso.Ho feta moo, ho iketsetsa le ho iketsetsa lisebelisoa ho ka boela ha ama lenane la ho qetela la lisebelisoa tse hlokahalang.