Granulator e omileng

Granulator e omeletseng, eo hape e tsejoang e le mochini o omileng oa granulation, ke sesebelisoa se ikhethileng se etselitsoeng ho bokella lisebelisoa tse omeletseng ntle le tlhoko ea li-binders tsa metsi kapa li-solvents.Ts'ebetso ena e kenyelletsa ho kopanya le ho etsa liphofshoana tse omeletseng kapa likaroloana ho li-granules, tseo ho leng bonolo ho li tšoara, ho li boloka le ho li tsamaisa.Sehloohong sena, re tla hlahloba melemo, molao-motheo oa ts'ebetso, le ts'ebeliso ea li-granulator tse omeletseng liindastering tse fapaneng.

Melemo ea Dry Granulation:

Ha ho Li-Liquid Binders kapa Solvents: Granulation e omileng e felisa tlhoko ea li-binders tsa mokelikeli kapa li-solvents tse sebelisoang hangata mekhoeng ea granulation ea metsi.Sena se fokotsa ho rarahana ha mokhoa oa granulation, se nolofatsa ho sebetsana le ho hloekisa, le ho felisa kotsi ea tšilafalo kapa mathata a tikoloho a amanang le li-binders tse thehiloeng mokelikeli.

Botsitso bo Ntlafetseng: Li-granules tse omileng li na le botsitso bo ntlafetseng ha li bapisoa le phofo kapa likaroloana tse hlephileng.Sebopeho se kopaneng sa li-granules se fokotsa karohano, se thibela ho monya mongobo, hape se ntlafatsa thepa ea phallo.Botsitso bona bo tiisa boleng ba sehlahisoa bo tsitsitseng mme bo fokotsa kotsi ea ho senyeha nakong ea polokelo kapa ea lipalangoang.

Ho boloka Litšenyehelo: Granulation e omileng e fana ka melemo ea litšenyehelo ka ho felisa tlhoko ea li-binders tsa metsi, lits'ebetso tsa ho omisa le lisebelisoa tse amanang le tsona.E fokotsa tšebeliso ea matla, nako ea tlhahiso, le litlhoko tsa tlhokomelo, e leng se bakang ho boloka litšenyehelo bakeng sa bahlahisi.

Thepa ea Granule e ka tloahelehang: Granule e omileng e lumella taolo e nepahetseng holim'a thepa ea granule, joalo ka boholo, sebopeho, boima le porosity.Sena se nolofalletsa bahlahisi ho hlophisa li-granules ho latela litlhoko tse ikhethileng tsa kopo, ho netefatsa ts'ebetso e nepahetseng le litšobotsi tse lakatsehang tsa sehlahisoa.

Molao-motheo oa ho sebetsa oa li-Granulator tse omileng:

Li-granulator tse omileng hangata li sebelisa mekhoa e 'meli ea mantlha: ho kopanya le ho sila.

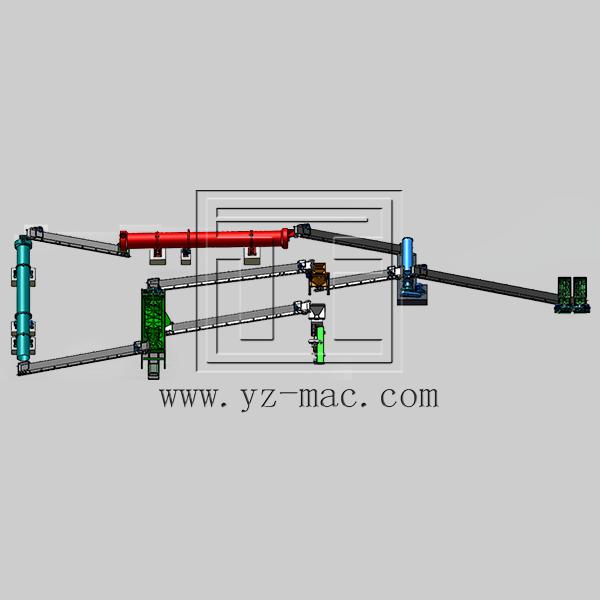

Compaction: Mokhahlelong oa ho kopanya, liphofshoana tse omeletseng kapa likaroloana li kenngoa ka phaposing ea granulation, moo para ea li-counter-rotating rolls kapa mochine oa khatiso o sebetsang ka khatello ea ho kopanya thepa.Thepa e kopantsoeng e etsa deformation ea polasetiki, e etsa ribone kapa lakane.

Ho sila: Ribone e kopantseng kapa lakane ebe e fetisoa ka mokhoa oa ho sila, o nang le sete ea lithipa kapa li-blades tse pshatlang thepa hore e be granules ea boholo bo lakatsehang.Li-granules tse sililoeng lia bokelloa 'me li ka kena mehatong e meng ea ts'ebetso, joalo ka ho sefa kapa ho roala, ha ho hlokahala.

Lisebelisoa tsa Dry Granulators:

Indasteri ea Meriana: Granulation e omileng e sebelisoa haholo ho etsa meriana bakeng sa tlhahiso ea matlapa, li-capsules le mefuta e meng e tiileng ea litekanyetso.E thusa ho hatella ka kotloloho ea phofo ea lithethefatsi hore e be li-granules, ho ntlafatsa phallo, ho ts'oana, le matlapa.Li-granulator tse omileng li loketse tlhahiso ea meriana e nyenyane le e kholo.

Indasteri ea Lik'hemik'hale: Ho sebelisoa ha granulation indastering ea lik'hemik'hale bakeng sa tlhahiso ea manyolo a granular, catalysts, pigments, le lihlahisoa tse ling tsa lik'hemik'hale.Ts'ebetso ena e etsa hore ho be le taolo e nepahetseng holim'a thepa ea granule, joalo ka boholo, letsoalo, le porosity, ho netefatsa boleng bo tsitsitseng ba sehlahisoa le litšobotsi tse ntlafalitsoeng tsa ho sebetsana le tsona.

Indasteri ea Lijo le Nutraceutical: Granulation e ommeng e sebelisoa indastering ea lijo le phepo e nepahetseng ho hlahisa metsoako ea granular, li-supplement tsa lijo le li-additives tsa lijo.E lumella ho etsoa ha mekhoa e tloaelehileng, mekhoa e laoloang ea tokollo, le phallo e ntlafetseng bakeng sa ts'ebetso e nepahetseng le boiketlo ba bareki.

Powder Metallurgy: Granulation e ommeng e bapala karolo ea bohlokoa ho metallurgy ea phofo, moo liphofshoana tsa tšepe li kopanngoang le ho granulated ho etsa li-feedstocks bakeng sa lits'ebetso tse latelang tse kang compaction, sintering le shape.Granulation e omeletseng e ntlafatsa phallo ea thepa, ho teteana le ho ts'oana ha phofo ea tšepe, ho nolofatsa ts'ebetso ea bona le ts'ebetso e latelang ea tlhahiso.

Qetello:

Li-granulator tse omeletseng li fana ka granulation e sebetsang hantle le e theko e boima ea thepa e omileng ntle le tlhoko ea li-binders tsa metsi kapa li-solvents.Ka melemo e kang ho ntlafala ha botsitso, ho boloka litšenyehelo, le thepa ea granule eo u ka e khonang, granulation e omeletseng e fumane lisebelisoa liindastering tse fapaneng, ho kenyeletsoa meriana, lik'hemik'hale, lijo, phepo e nepahetseng le phofo ea metallurgy.Ka ho sebelisa li-granulator tse omeletseng, bahlahisi ba ka fihlela boleng bo ts'oanang ba sehlahisoa, ba ntlafatsa litšoaneleho tsa bona, le ho ntlafatsa lits'ebetso tsa bona tsa tlhahiso.