graphite granule extrusion mokhoa oa granulation

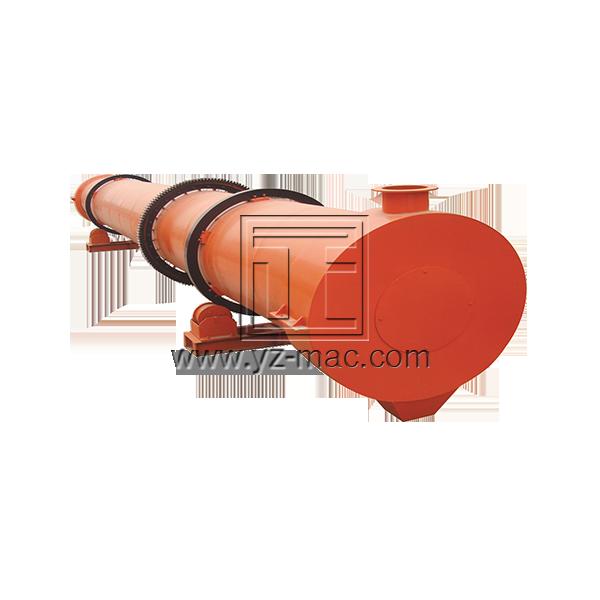

Mokhoa oa graphite granule extrusion granulation ke mokhoa o sebelisoang ho hlahisa li-granules tsa graphite ka extrusion.E kenyelletsa mehato e mengata eo hangata e lateloang ts'ebetsong:

1. Tokisetso ea Boitsebiso: Phofo ea graphite, hammoho le li-binders le li-additives tse ling, li kopantsoe hammoho ho etsa motsoako oa homogeneous.Sebopeho le karolelano ea lisebelisoa li ka fetoloa ho latela thepa e lakatsehang ea li-granules tsa graphite.

2. Ho fepa: Motsoako o lokiselitsoeng o kenngoa ka har'a extruder, e nang le mokhoa oa ho fepa.Mokhoa oa ho fepa o tiisa phepelo e tsitsitseng le e laoloang ea motsoako ho kamoreng ea extrusion.

3. Extrusion: Ka hare ho kamoreng ea extrusion, motsoako o tlas'a khatello e phahameng le matla a ho kuta.Sekurufu se potolohang kapa mochini oa piston ka har'a extruder se qobella thepa ka har'a dae, e bopang thepa e ntšitsoeng ka mokhoa o lakatsehang oa granules ea graphite.Maemo a khatello le mocheso a ka ntlafatsoa ho fihlela thepa e lakatsehang ea granule.

4. Ho Seha: Ha thepa ea graphite e ntšitsoeng e tloha lefing, e khaoloa ka bolelele bo itseng ka mochine oa ho itšeha.Sena se ka etsoa ka ho sebelisa li-blades kapa lisebelisoa tse ling tsa ho itšeha.

5. Ho omisa: Li-granules tse sa tsoa khaoa tsa graphite li ka 'na tsa e-na le mongobo o tsoang ts'ebetsong ea extrusion.Ka hona, ka tloaelo li omisitsoe ka mokhoa oa ho omisa ho tlosa mongobo leha e le ofe o feteletseng le ho matlafatsa botsitso ba tsona.

6. Cooling le Sizing: Li-granules tse omisitsoeng tsa graphite li ka 'na tsa e-ba le mokhoa oa ho pholisa ho tsoela pele ho li tsitsisa.Li ka 'na tsa sefa kapa tsa hlahlojoa ho finyella kabo ea boholo bo lakatsehang.

7. Ho paka: Mohato oa ho qetela o kenyelletsa ho paka li-granules tsa graphite ka har'a lijana kapa mekotla e loketseng bakeng sa polokelo kapa lipalangoang.

Litekanyetso tse khethehileng le lisebelisoa tse sebelisoang ts'ebetsong ea extrusion granulation li ka 'na tsa fapana ho itšetlehile ka litšobotsi tse lakatsehang tsa li-granules tsa graphite, tse kang boholo ba likaroloana, boima le matla.Baetsi ba lisebelisoa tsa graphite granule extrusion ba ka fana ka lintlha tse ling le tataiso mabapi le ts'ebetso.https://www.yz-mac.com/roll-extrusion-compound-fertilizer-granulator-product/