Iho hlahisoa ha Organic Fertilizer Productaba Line

Mohala ona oa tlhahiso ea manyolo o entsoeng ke rona o ka hlahisa lithane tse 30,000 tsa li-granules tsa manyolo a manyolo ka selemo, 'me lithane tsa litšila tse fapaneng tsa tlhaho li fetoloa manyolo a tlhaho.Semela sa manyolo a bioorganic ha se fetole litšila feela (joalo ka moiteli oa likhoho, litšila tsa kichineng joalo-joalo) hore e be letlotlo, empa hape se fokotsa tšilafalo ea tikoloho.Sebopeho sa granular e ka ba cylindrical kapa spherical, e loketseng ho tsamaisoa le ho sebelisoa.Thepa ke ea boikhethelo ho latela tlhoko ea hau ea 'nete.

Lisebelisoa tse ruileng tsa Raw Material

Semela sa manyolo a manyolo se na le lisebelisoa tse ngata.Thepa e ka fapana bakeng sa lisebelisoa tse fapaneng.

1.Litšila tsa liphoofolo, tse hōlileng ka ho feletseng tsa liphoofolo, tse kang khoho, kolobe, letata, likhomo, linku, pere, mmutla, masala a liphoofolo, joalo ka lijo tsa tlhapi, lijo tsa masapo, lesiba, boea, mantle a silkworm, masala a biogas, joalo-joalo.

2.Tšinyo ea temo.Lehlaka la sejalo, morara, phofo ea soya, rapeseed meal, cottonseed meal, caster bean meal, tee seed meal, yeast powder, masalla a mushroom, joalo-joalo.

3.Litšila tsa indasteri.Vinasse, masala a asene, litšila tsa manioc, seretse se hloekisang, masala a litlama, masala a boea, joalo-joalo.

4.Matlapa a masepala.Seretse sa noka, seretse sa ponto, seretse sa foro, seretse sa leoatle, seretse sa letša, seretse sa likhoerekhoere, acid e humic, turf, lignite, danty, fofa, molora, joalo-joalo.

5.Lithōle tsa ka tlung.Litšila tsa kichineng, joalo-joalo.

6. Li-organics tse nkiloeng kapa tse nang le concentrated, li-seaweed extract, tlhapi ea tlhapi, joalo-joalo.

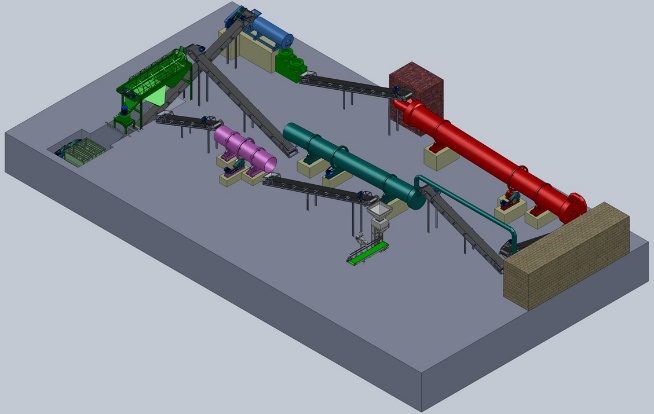

Mainhlomellament of 30,000 Ton Organic Fertilizer Granulator Line.

1.Cmothinya oa ompost

1.Cmothinya oa ompost

Mokhoa oa ho belisa o bolisa litšila tsa tlhaho ebe o li fetola manyolo a tlhaho.Re fana ka mefuta e fapaneng ea ho fetola manyolo ka litlama: mochini o fetolang manyolo ka litlama o ikemetseng, mochini o fetolang manyolo ka makhetlo a mabeli, hydraulic compost turner, groove type turner, le groove mofuta oa hydraulic compost turner, tseo kaofela li fumaneng botumo bo boholo 'marakeng oa machabeng.U ka khetha ho latela lisebelisoa tsa 'nete, libaka le litlhoko tsa sehlahisoa se felileng.

2.Semi-wet Material Crusher

Lisebelisuoa tse lomositsoeng li kena ka har'a sesebelisoa sa semi-wet material crusher, se ka pshatlang thepa e lomositsoeng ka mongobo ka hare ho 30%.Boholo bo ka fihla ho 20-30 mesh, ho fihlela tlhokahalo ea granulation.

3.Hmotsoako oa bochabela

Ka mor'a ho senya, lisebelisoa tse thusang li kenngoa ka har'a lisebelisoa ho ea ka mokhoa oa ho kopanya le ho kopanngoa ka mixer.Re fana ka mixer e otlolohileng ea shaft e le 'ngoe le shaft e habeli hore u kopanye lisebelisoa ka ho lekana.

4.New Type Organic Fertilizer e inehetseng Granulator

Mochine ona o ka thusa ho fokotsa matla a senyehileng nakong ea ho omisa, hobane li-granules li ka hlahlojoa hang-hang ka mor'a ts'ebetso ea granulation.Ho hloeka ha li-granules tsa manyolo a manyolo ho ka fihla holimo ho 100%, e leng se etsang hore tlhahiso e hloekileng ea manyolo a manyolo e phethahale le ho finyella litlhoko tsa bareki ka ho toba.Boleng ba li-granules tsa manyolo bo ka netefatsoa ka nako e le 'ngoe.Kahoo mochini ona o hlahisoa ka tšebeliso e tlase ea matla, litšenyehelo tse tlase tsa tlhahiso le boleng bo phahameng ba tlhahiso mme o nkuoa e le khetho e ntle ka ho fetisisa bakeng sa tlhahiso e hloekileng ea manyolo a manyolo.

5.BMochini oa sebopeho sohle

Mochine ona o ka bopa li-granules tse fapaneng tsa manyolo tse hlahisoang ke granulator ea extruding kapa disc granulator, 'me li-granule tsena li tla ba le boholo bo lekanang, bo pota-potile, boreleli le matla a maholo ka mor'a hore ho be le bolo, tekanyo ea ho etsa bolo ea manyolo e tla nyoloha. ho isa ho 98%.E na le melemo ea ho se be le thepa ea ho khutla, lebelo le phahameng la ho etsa bolo, matla a phahameng le ponahalo e ntle.

6.Rotary Drum Dryer le Cooler

Li-granule tse tsoang ho granulator li na le mongobo o phahameng 'me li lokela ho omisoa ho finyella maemo.Rotary drum dryer e nka moea o chesang ho omisa granules.

Li-granules tse omisitsoeng li na le mocheso o phahameng haholo 'me li lokela ho pholile ho thibela ho baka.Mochini oa ho futhumatsa moropa oa Rotary o sebelisoa hammoho le se omisang ho tlosa mongobo le ho theola mocheso.

7.Rotary Screening Machine

Li-granules tsa manyolo tse pholileng li kena mochineng oa ho hlahloba rotary.Li-granules tse sa tšoaneleheng li khutlisetsoa ho crusher.Li-granules tse tšoanelehang li romeloa mochine oa ho roala.

8.Rotary CoaMochini oa tšepe

Mochini oa ho roala oa Rotary ke sesebelisoa sa ho roala li-pellets ka phofo kapa metsi.The.thepa e etselitsoe ka ho khetheha ho ea ka litlhoko tsa ts'ebetso ho sebopeho sa ka hare.Mokhoa oa ho roala o ka thibela ka katleho caking ea manyolo le ho finyella phello ea ho lieha ho lokolloa.

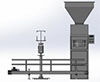

9.GRanules Packing Machine

Mochini o pakang li-granules o sebelisetsoa ho paka palo ea li-granules tsa manyolo.E na le mochini oa ho bekha le oa ho paka o ikemetseng, conveyor, mochini o tiisang le mochini o fepang.Ho nepahala ha boima bo phahameng, ts'ebetso e bonolo.Manyolo a pakiloeng a tla bolokoa hore a rekisoe.

Ftse jangofMohala oa Tlhahiso ea Fertilizer ea Organic

1.Adopt semi-wet materials crusher, ba le matla a ho ikamahanya le maemo a mongobo.

2.Granules polishing machine e etsa li-granules tsa spherical tse nang le boholo bo lekanang, bokaholimo bo boreleli le matla a phahameng.E loketse ho hokahana le li-granulator tse fapaneng.

3.Belt conveyor ke le lisebelisoa tse ling tse tšehetsang li sebelisoa ho hokahanya mohala oohle.

Sebopeho sa 4.Compact, ts'ebetso e tsitsitseng, ts'ebetso e bonolo le tlhokomelo.

5.Thepa ke ea boikhethelo ho latela litlhoko tsa hau tsa nnete.

TEchnical Data ea 30,000 T/Y Organic Fertilizer Production Line

Mohala oa tlhahiso - Karolo ea ho belisoa

| Che. | Lebitso | Mohlala | Matla (KW) | Bongata | Chelete (li-yuan tse likete tse leshome) | Setšoantšo | Tlhaloso |

| 1 | Fepa ea forklift | CWL-2040 | 7 | 1 | 2.31 |

| 1. Amohela sebopeho se arohaneng sa ho jara le ho hula ho ntlafatsa matla a ho jara mojaro oa fepelo.2. Forklift feeder e na le letlooa le khahlanong le smash ho fokotsa tšusumetso ea lijo tse ngata.3. Fepa ea forklift e na le shaft e susumetsang le mochine o sisinyehang ho thibela ho thibela lisebelisoa tse phahameng tsa metsi. 4. Karolo e fetisang ea lebanta le ka tlaase ke lebanta la lebelo le feto-fetohang, le ka laolang ka nepo palo ea lijo. 5. Boholo ba boema-kepe ba ho fepa bin: 2m * 3m (boholo ba boemo ba enjene le se fokotsang ha bo kenyellelitsoe) |

| 2 | Mochini o phetholang moiteli oa Crawler | FDJ-2400 | 38 ~ 55 enjene ea diesel | 1 | 12.1 |  | 1. Sehlahisoa sena se amohela thekenoloji ea bohlale ba mechine ho hlokomela lebelo le sa fetoheng la ho tsamaea le ho phethoha ha mochine, e leng se ka behang ka nepo lebelo la lebelo la lebili le lebili le thinyetsang ho latela mofuta oa thepa ho fumana tlhahiso le boleng bo holimo.2. Matla ke enjene ea diesel ea 81 horsepower e otlolohileng ka metsi, e nang le matla a lekaneng, ts'ebetso e phahameng le tšebeliso e tlaase ea mafura.3. Mochine ona o amohela theknoloji ea setsebi ea ho reteleha sebakeng, 360 ° sesebelisoa sa ho chencha se hlabang, se nang le tsamaiso e bonolo, sebaka se senyenyane sa fatše le ts'ebetso e loketseng ea sebaka. 4. Tsohle motlakase konopo switjha taolo, tenyetsehang le bonolo. 5. E le ho ikamahanya le ts'ebetso tlas'a tikoloho ea kutu e matla, foreime le poleiti ea balebeli kaofela li teteaneng ka thepa e tloaelehileng ea naha ts'ebetsong ea rona ea tlhahiso. 6. Hydraulic mode e ka amoheloa ho lokisa sebaka se pakeng tsa shaft stacking le fatše.Thibela thipa e phetholang shaft ho thetsa fatše.(Ho ea ka litlhoko tsa bareki) 7. Ho hlomelloa ka tekesi. 8. Moeeng oa moea o ka kenngoa ho latela litlhoko tsa bareki.

|

| 3 | Mochine oa ho hlahloba | GS-1240 | 3*2 | 2 | 4.16 |  | 1. Skrine e entsoe ka tšepe e sa hloekang ho thibela ho bola.2. Ho ea ka litlhoko tsa moreki, sesebelisoa sa anti-stick net se ka eketsoa.3. Mosebetsi oa mochine ona oa ho hlahloba ke ho hlahloba likaroloana tse omisitsoeng, lihlahisoa tse felileng li kena ts'ebetsong ea ho paka, 'me lihlahisoa tsa litšila li khutlela ho senya hape.

|

| 4 | Mosinya o Mong | LP-800 | 30 | 1 | 2.3 |

| 1. Crusher e amohela sebopeho sa motsoako oa lehare la ketane, le ka senyang thepa ka metsi a ka tlase ho 40% ho itokisetsa granulation.2. Ketane e entsoe ka alloy e phahameng ea manganese, 'me lehare le entsoe ka tšepe ea selemo, e nang le molemo oa ho hanyetsa ho apara ka nako e telele.3. Rotor e leka-lekana ka matla 'me e ka sebetsa ka mokhoa o tsitsitseng ntle le motheo. 4. Kalafo ea ho tlosa lerōle e etsoa koung ea ho ntša metsi ho thibela lerōle le leholo. 5. Crusher e na le bokhoni bo phahameng ba ho senya 'me ha ho bonolo ho khomarela le ho thibeloa.E na le fensetere ea ho shebella. 6. Bophara ba barrel ke 1000mm, 'me botenya ba lebota ke 10mm. |

Mohala oa tlhahiso - Karolo ea granulating

| Che. | Lebitso | Mohlala | Matla (KW) | Bongata | Chelete (li-yuan tse likete tse leshome) | Setšoantšo | Tlhaloso |

| 6 | Double -helix tshekaletseng Crusher | HC-80 | 11 | 2 | 4.2 |  | 1. Sebopeho sa li-helix tse peli se amoheloa ka lehare la ho kopanya, le tiisang hore esita le ho kopanya le ho sebetsa hantle haholo.2. Lehare la ho kopanya le entsoe ka thepa e matla le e sa sebetseng, e leng nako e telele haholoanyane. 3. Tlhaloso e fokolang pakeng tsa rotor le khetla e ka fetoloa hore e be haufi le zero, ka katleho e fokotsa masala a thepa. 4. Botenya ba 'mele: 6mm |

| 7 | Granulator e ncha ea manyolo a manyolo | JZLG-1000 | 75 | 1 | 8.19 |  | 1. Granulator ke sehlahisoa se nang le tokelo ea molao sa k'hamphani ea rona.2. Karolo ea ho kopana pakeng tsa granulator le thepa e entsoe ka 304 tšepe e sa hloekang. 3. Hlooho ea sesebelisoa ea ka hare ho kopanya lisebelisoa e amohela hlooho ea sesebelisoa sa carbide. 4. Matla a tlhahiso: 2.5-3.5t / h 5. Boemo ba ka ntle: 4700 * 2350 * 1600mm |

| 8 | Rotary dryer | HG-15150 | 15 | 1 | 12.05 |  | 1. Silinda ea se omisitsoeng ke 14mm e teteaneng e kopantsoeng ea spiral tube, e nang le melemo ea ho tsepamisa mohopolo o phahameng, ho tiea ho matla le ts'ebetso e tsitsitseng.Botenya ba poleiti ea ho phahamisa ke 8mm.2. Giarring, roll lebanta, idler le bracket kaofela ke castings tšepe. 3. Fen e kentsoeng ea moralo e lokisitsoe ka botsitso bo tsitsitseng le bo matla, kahoo e tsamaea hantle 'me e na le matla a phahameng. 4. Amohela mokhoa oa ho omisa ka tlase.Moea oa thepa le mohloli oa mocheso o kena ka har'a thepa ea ho omisa ho tloha ka lehlakoreng le le leng. 5. Mekhahlelo e nepahetseng ea ts'ebetso e leka-lekanya mohloli oa mocheso, lisebelisoa le tataiso ea moea, kahoo e ntlafatsa haholo ts'ebetso ea mocheso le ho fokotsa tšebeliso ea matla a ho omisa ka 30-50% kapa ho feta. |

| 9 | Rotary cooler | HG-12120 | 7.5 | 1 | 11.05 |  | 1. Mokotla oa mochine o pholileng ke 14mm e teteaneng e kopantsoeng ea spiral tube e nang le melemo ea ho tsepamisa mohopolo o phahameng, ho tiea ho matla le ts'ebetso e tsitsitseng.Botenya ba poleiti ea ho phahamisa ke 6mm.2. Ring ea li-gear, rolara le bracket li entsoe ka tšepe. 3. Fen e kentsoeng ea moralo e lokisitsoe ka botsitso bo tsitsitseng le bo matla, kahoo e tsamaea hantle 'me e na le matla a phahameng. 4. Mekhahlelo e nepahetseng ea ts'ebetso ho leka-lekanya "lisebelisoa le moea", e le ho ntlafatsa haholo ts'ebetso ea ho pholisa le ho etsa hore tšebeliso ea matla a pholileng e fokotsehe ka 20-50% kapa ho feta. |

| 10 | Mochine oa ho roala | BM-10400 | 5.5 | 1 | 4.29 |  | 1. 'Mele oa cylinder oa mochine o kenngoe ka letlapa le khethehileng la rabara kapa lesela la tšepe le sa hloekeng le nang le acid.2. Mochini oa ho roala o sebelisoa hammoho le tsamaiso ea spray ea phofo e omileng. 3. Sistimi ea phetisetso le bracket ea rolara ea mochini oa ho roala kaofela ke li-castings tsa tšepe. |

| 11 | Mochini oa ho paka oa bongata | QP-301127 | 1.1 | 1 | 4.2 |  | 1. Karolo ea ho kopana le thepa e entsoe ka 304 tšepe e sa hloekang.2. Ho fepa, ho metha, ho kenya mekotla le ho laolla ka nako e le 'ngoe.Boloka karolo ea boraro ea nako ea ts'ebetso. 3. Li-sensor tse tsoang linaheng tse ling, li-actuator tsa pneumatic tse tsoang linaheng tse ling, mosebetsi o ka tšeptjoang, tlhokomelo e bonolo.Ho nepahala ha tekanyo ke ho kopanya kapa ho tlosa likarolo tse peli ho sekete. 4. Mefuta e mengata e mengata, e nepahetseng e phahameng, e nang le mochine oa seam conveyor o phahamisang tafole, mochine o nang le merero e mengata, bokhoni bo phahameng. 5. Sekala sa ho paka bakete (ho kenyeletsoa mochini oa ho paka, mochini o tiisang le mochini o hokahaneng oa lebanta) |

Mohala oa tlhahiso - Karolo e tšehetsang

| Che. | Lebitso | Lebitso | Matla(KW) | Bongata | Chelete (li-yuan tse likete tse leshome) | Setšoantšo | Tlhaloso |

| 12 | Moqomo oa polokelo | 1 | 0.455 |  | Meqomo ea polokelo e sebelisoa haholo mehalang e fapaneng ea tlhahiso ea manyolo, hangata e bokella lisebelisoa ho conveyor ea lebanta ebe e isoa tšebetsong e tebileng e latelang.Moqomo o theko e tlaase ebile oa tšoarella. | ||

| 13 | Chain crusher bakeng sa lisebelisoa tse khutlisitsoeng | LP-600 | 15 | 1 | 0.105 |  | 1. Lerako le ka ntle la crusher le entsoe ka poleiti ea tšepe ea manganese e boima ba 8mm.2. Ketane ea crusher e entsoe ka alloy e phahameng ea matla. 3. Lintho tse senyang li tšoana, ha ho bonolo ho khomarela lebota, 'me ho bonolo ho li hloekisa. 4. Lerako le ka hare le ka etsoa ka rabara kapa tšepe e sa hloekang (ho ea ka litlhoko tsa bareki) ho finyella bokaholimo bo boreleli le ho hloekisa habonolo. 5. Menyako e kenang ka potlako ea ho kena e hlophisitsoe ka mahlakoreng a mabeli a 'mele.'Mele o ka sehloohong le sesebelisoa sa phetisetso li kenngoa motheong o tšoanang o entsoeng ka tšepe,' me mochine o ts'oarellang o kenngoa ka tlas'a setsi mme o kopantsoe le motheo. 6. Boholo ba silindara: 0.6m |

| 14 | 1.2 * 2M polokelo ea polokelo | - | 1 | 0.95 | Meqomo ea polokelo e sebelisoa haholo mehalang e fapaneng ea tlhahiso ea manyolo, hangata e bokella lisebelisoa ho conveyor ea lebanta ebe e isoa tšebetsong e tebileng e latelang.Moqomo o theko e tlaase ebile oa tšoarella.Boholo bona ke 1.2*2M. | ||

| 15 | Mochini oa ho paka oa bongata | QP-301127 | 1.1 | 1 | 4.2 |  | 1. Karolo ea ho kopana le thepa e entsoe ka 304 tšepe e sa hloekang.2. Ho fepa, ho metha, ho kenya mekotla le ho laolla ka nako e le 'ngoe.Boloka karolo ea boraro ea nako ea ts'ebetso. 3. Li-sensor tse tsoang linaheng tse ling, li-actuator tsa pneumatic tse tsoang linaheng tse ling, mosebetsi o ka tšeptjoang, tlhokomelo e bonolo.Ho nepahala ha tekanyo ke ho kopanya kapa ho tlosa likarolo tse peli ho sekete. 4. Mefuta e mengata e mengata, e nepahetseng e phahameng, e nang le mochine oa seam conveyor o phahamisang tafole, mochine o nang le merero e mengata, bokhoni bo phahameng. 5. Sekala sa ho paka bakete (ho kenyeletsoa mochini oa ho paka, mochini o tiisang le mochini o hokahaneng oa lebanta) |

| 16 | 'mokelli oa lerole oa leholiotsoana | SXXC-1200 | - | 2 | 5.4 |  | 1. Mokelli oa lerōle oa Leholiotsoana o bonolo ka sebopeho, o bonolo ho o etsa, ho kenya, ho boloka le ho laola, 'me o theko e tlaase ka lichelete tsa thepa le litšenyehelo tsa ts'ebetso.2. Mokelli oa lerōle oa leholiotsoana o entsoe ka phala e kenang, phala ea ho ntša metsi, 'mele oa cylinder,' mele oa cone le bakete ea molora. 3. Karolo e 'ngoe le e' ngoe ea pokello ea lerōle ea leholiotsoana e na le tekanyo e itseng ea boholo.Bophara ba mokelli oa lerōle, boholo ba seketsoana sa moea le bophara ba phala ea ho ntša metsi li baloa ka nepo ke moenjiniere ho netefatsa phello e ntle ka ho fetisisa ea ho tlosa lerōle. |

| 17 | 6C e khothalelitsoeng ho theha fan | SXYF-12C | 15 | 1 | 0.8 |  | 1.The induced draft fan e lekantsoe ke static le dynamic balance, kahoo e tsamaea hantle 'me e na le matla a phahameng.Fene e kentsoeng le phala e kopanyang li tsamaisana le se omisang.2. The impeller e entsoe ka 10 recumbent mapheo diblades, kobehileng ka pele poleiti le bataletseng ka morao poleiti.Thepa ea eona e entsoe ka poleiti ea koporo kapa alloy e entsoeng ka aluminium, 'me ka ho leka-lekanya ho leka-lekana ho matla le ho tsitsitseng, ts'ebetso e ntle ea moea, ts'ebetso e phahameng, ts'ebetso e boreleli. 3. Mohaho o kenang moeeng o entsoe ka botlalo 'me o kenngoa ka lehlakoreng la fene.Karolo e bapileng le tataiso ea axial ke sebopeho se kobehileng, se nolofalletsang khase ho kena ho impeller hantle le ka tahlehelo e nyane ea moea. |

| 18 | Ho tlosa lerōle la likharetene tsa metsi | SXSC-1500 | - | 1 | 1.95 | 1. Lesira la metsi le tlosang lerole la metsi le pompa metsi ho ea ka holim'a lerōle ka pompo ea metsi e nang le khatello e phahameng.Khase ea flue le lerōle tse hlahisoang ts'ebetsong ea tlhahiso li ntšoa ka mochine o ikhethileng o entsoeng ka mechine e meraro.2. Metsi a litšila a ka kenngoa ka ho toba ka tanka ea ho belisoa ho felisa tšilafalo ea bobeli, 'me palo ea metsi a litšila e nyenyane haholo. | |

| 19 | 8C e hlahisitsoeng ke fan fan | SXYF-8C | 22 | 1 | 1.8 |  | 1.The induced draft fan e lekantsoe ke static le dynamic balance, kahoo e tsamaea hantle 'me e na le matla a phahameng.Fene e kentsoeng le phala e kopanyang li tsamaisana le se omisang.2. The impeller e entsoe ka 10 recumbent mapheo diblades, kobehileng ka pele poleiti le bataletseng ka morao poleiti.Thepa ea eona e entsoe ka poleiti ea koporo kapa alloy e entsoeng ka aluminium, 'me ka ho leka-lekanya ho leka-lekana ho matla le ho tsitsitseng, ts'ebetso e ntle ea moea, ts'ebetso e phahameng, ts'ebetso e boreleli. 3. Mohaho o kenang moeeng o entsoe ka botlalo 'me o kenngoa ka lehlakoreng la fene.Karolo e bapileng le tataiso ea axial ke sebopeho se kobehileng, se nolofalletsang khase ho kena ho impeller hantle le ka tahlehelo e nyane ea moea. |

| 20 | Lebanta la conveyor | B500 | 57 | 126(850/m) | 10.71 |

| 1. The foreimi e amohela 10mm kanale tšepe.2. Lirolara tsohle ke lirolara tse tloaelehileng tsa naha. 3. Li-gear tsa phetiso le litulo tsa ho jara ke li-castings tsa tšepe tse teteaneng. |

| 21 | Khabinete e kopaneng ea taolo ea motlakase | 3.3 | Likarolo tsa motlakase ke mofuta oa ZhengTai | ||||

| 22 | Pipe bakeng sa ho omisa le ho pholile | 2.8 | 1. Pipe ea ho kopanya ea dryer le cooler. | ||||

| Kakaretso | 97.32(EXW) | ||||||

| Mohloli oa khase (pompo ea moea bakeng sa sekala sa ho paka), thapo, terata, lisebelisoa tsa tšepe tse rekiloeng ke bareki. | |||||||

Tlhokomeliso: Ts'ebetso ena ke ea litšupiso feela mme e ipapisitse le litlhoko tsa bareki, maemo a sebaka sa marang-rang le lisebelisoa tse tala.

Nako ea poso: Sep-27-2020