INtrotheolelo

Sehlopha sohle sa mohala oa tlhahiso, se nang le mechini e tsoetseng pele le e sebetsang hantle haholo, se ka fihlela tlhahiso ea manyolo a kopaneng a 30,000 selemo le selemo.Ho ea ka matla, lisebelisoa tsa rona tsa manyolo tse kopantsoeng li arotsoe ka lithane tse 20,000, lithane tse 30,000 le lithane tse 50,000.Bareki ba ka khetha mokhoa ofe kapa ofe oa tlhahiso ka ho rata.Mokhoa oa tlhahiso ea manyolo o kopantsoeng o na le matsete a tlase le phaello e ntle ea moruo.Thepa e felletseng e ajoa ka mokhoa o kopanetsoeng, ka mokhoa o utloahalang le oa saense.Mechini eohle, joalo ka motsoako oa manyolo, granulator ea manyolo, mochini o koahelang manyolo joalo-joalo. Matha hantle, ka likarolo tsa ho boloka matla, litšenyehelo tse tlase tsa tlhokomelo, le ts'ebetso e bonolo.

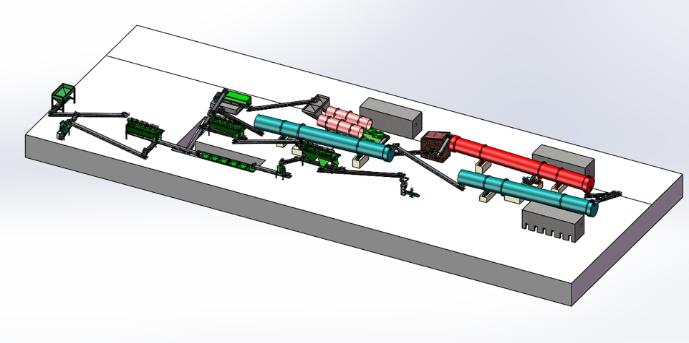

Working Mokhoa oa Medium ScaleMohala oa Tlhahiso ea Motsoako oa Motsoako

Mokhoa oa tekheniki oa mohala oa tlhahiso ea manyolo ka kakaretso o tsamaea tjena: ho lekanya lisebelisoa, ho kopanya ka ho lekana, granulating, ho omisa, ho pholisa, ho roala manyolo a kopaneng, ho paka.

1.MSistimi ea batching ea lisebelisoa:Ho latela tlhoko ea 'maraka le boikemisetso ba mobu oa lehae, ho latela karolo e itseng ea kabo ea urea, ammonium nitrate, ammonium chloride, ammonium sulphate, ammonium phosphate (monoammonium phosphate, diammonium phosphate, calcium e boima, calcium e akaretsang), potasiamo chloride (potasiamo chloride). sulphate) le lisebelisoa tse ling tse tala.Ka sekhahla sa lebanta ho ea ka karolo e itseng ea li-additives, trace elements, joalo-joalo Ho ea ka tekanyo ea foromo, lisebelisoa tsohle tse tala li tsamaisoa ka mokhoa o ts'oanang ka lebanta ho ea ho motsoako.Mokhoa ona o bitsoa premix.E etsa bonnete ba hore batching e nepahetse ho latela foromo mme e etsa hore ho be le ts'ebetso e phahameng e tsoelang pele ea batching.

2.Rho kopanya lisebelisoa tsa aw:khetho ea motsoako o otlolohileng e leng karolo ea bohlokoa tlhahisong, o thusa ka botlalo ho kopanya lisebelisoa tse tala hape, lihlahisoa tse phahameng tsa granules.Re etsa motsoako o otlolohileng oa shaft e le 'ngoe le mochini o kopanyang oa shaft habeli e le hore bareki ba rona ba ka khetha e nepahetseng ho latela tlhahiso le khetho ea bona.

3.Monontsha granulating:karolo ea mantlha ea mohala oa tlhahiso ea manyolo a kopaneng.Bareki ba ka khetha disc granulator, rotary drum granulator, roller extrusion granulator kapa motsoako oa manyolo granulator ho latela tlhoko ea 'nete.Mona re khetha rotary drum granulator.Ka mor'a ho kopanya ka mokhoa o ts'oanang, lisebelisoa li fetoloa ke conveyor ea lebanta ho granulator ho kena ka har'a likaroloana tsa boholo bo lekanang.

4. Mokhoa oa ho omisa le ho omisa menontsha:Mochini oa rona oa ho omisa drum oa rotary o phahameng haholo ke sesebelisoa sa ho omisa ho fokotsa mongobo oa lihlahisoa tsa ho qetela.Ka mor'a ho omisa, mongobo oa motsoako oa motsoako o tla fokotseha ho tloha ho 20-30% ho ea ho 2% -5%.Kamora ho omisa, lisebelisoa tsohle li hloka ho romelloa ka sehatsetsing.Mochini oa ho futhumatsa moropa oa rotary o hokahana le mochini o omisang rotary o nang le conveyor ea lebanta, ho tlosa lerōle le ho hloekisa mokelikeli hammoho, o ka ntlafatsang ts'ebetso ea ho pholisa le sekhahla sa ts'ebeliso ea matla a mocheso, ho fokotsa matla a mosebetsi, le ho tlosa mongobo oa mocheso. manyolo.

5.Ftlhahlobo ea ertilizer:ka mor'a ho pholile, ho ntse ho e-na le lisebelisoa tsa phofo lihlahisoa tsa ho qetela.Lichelete tsohle le likaroloana tse kholo li ka hlahlojoa ka mochini oa rona oa ho hlahloba meropa oa rotary.Ebe likotlo tse tsamaisoang ka lebanta conveyor li khutlela motsoako o tšekaletseng bakeng sa ho kopanya le ho bokelloa bocha ka lisebelisoa tse tala.Le hoja likaroloana tse kholo li hloka ho pshatleha ka har'a chain crusher pele ho granulating.Lihlahisoa tse felileng li fetisetsoa mochining o kopanyang manyolo.Ka tsela ena, potoloho e feletseng ea tlhahiso e thehoa.

6.CHo roala monontša ka ompound:mochini oa ho roala moqomo oa rotary o entsoeng ke rona o tsamaisoa ke enjene e kholo, lebanta, pulley le shaft ea koloi.Haholo-holo e sebelisoa ho apara seaparo se ts'oanang sa filimi e sireletsang holim'a manyolo a kopantsoeng, a thibelang borokho ba letsoai ka katleho le ho monya manyolo a manyolo, 'me a etsa hore likaroloana li be boreleli haholoanyane.Ka mor'a ho roala, ho tla ts'ebetso ea ho qetela ea tlhahiso eohle-ho paka.

7.FSistimi ea ho paka ea ertilizer:mochini oa ho paka othomathike oa bongata o amoheloa ts'ebetsong ena.E na le mochini oa ho bekha le oa ho paka o ikemetseng, sistimi ea lipalangoang, mochini o tiisang.Feed bin le eona e ka hlomelloa ho latela litlhoko tsa moreki.E khona ho hlokomela sephutheloana sa thepa ka bongata, joalo ka manyolo a manyolo le manyolo a kopaneng, mme e se e sebelisoa haholo fekthering ea ho lokisa lijo, mohala oa tlhahiso ea indasteri, jj.

Amolemo oa Mohala oa Tlhahiso e Phahameng ea Motsoako oa Motsoako oa Tlhahiso ea Motsoako

1.Wide raw materials range.

Mefuta e fapaneng ea lisebelisoa tse tala e loketse ho etsa manyolo a kopaneng, joalo ka meriana, lik'hemik'hale, lijo le lisebelisoa tse ling tse tala.

2.High poelo ya monontsha.

Mohala ona oa tlhahiso o ka hlahisa likhahla tse fapaneng tsa manyolo a kopaneng ho latela karo-karolelano ea lisebelisoa tse tala.

3.Theko e tlase.

Ua tseba hore mechini eohle ea manyolo e etsoa ke rona.Ha ho na motho ea bohareng, ha ho na barekisi, ho bolelang hore re barekisi ka kotloloho.Re etsa, 'me re etsa khoebo ea kantle ho naha, re holisa melemo ea bareki ba rona ka matsete a tlase.Ntle le moo, hoa khoneha hore bareki ba rona ba ikopanye le rona ka nako haeba ho na le mathata a tekheniki kapa ho bokella lipelaelo.

4.Hantle sebopeho sa 'mele.

Moiteli o kopantsoeng o hlahisoang ke mohala oa rona oa tlhahiso o na le monyo o monyane oa mongobo, 'me o bolokeha habonolo, o loketseng haholo ts'ebeliso ea mochini.

5.Tlhaloso eohle ea mohala oa tlhahiso ea manyolo e bokella lilemo tsa boiphihlelo ba tekheniki le tlhahiso.

Ke mokhoa o phahameng oa tlhahiso ea manyolo le matla a tlaase a tlhahiso ea manyolo, a fetotsoeng le a entsoeng, a atlehileng ho rarolla mathata a ts'ebetso e tlaase le ea theko e phahameng lapeng le linaheng tse ling.

Nako ea poso: Sep-27-2020