E 'ngoe ea melemo e meholo ea ho sebetsa le Yi Zheng ke tsebo ea rona e felletseng ea sistimi;ha re litsebi feela karolong e le 'ngoe ea ts'ebetso, empa ho e-na le hoo, karolo e' ngoe le e 'ngoe.Sena se re lumella ho fa bareki ba rona pono e ikhethang ea hore na karolo ka 'ngoe ea ts'ebetso e tla sebetsa hammoho joang ka kakaretso.

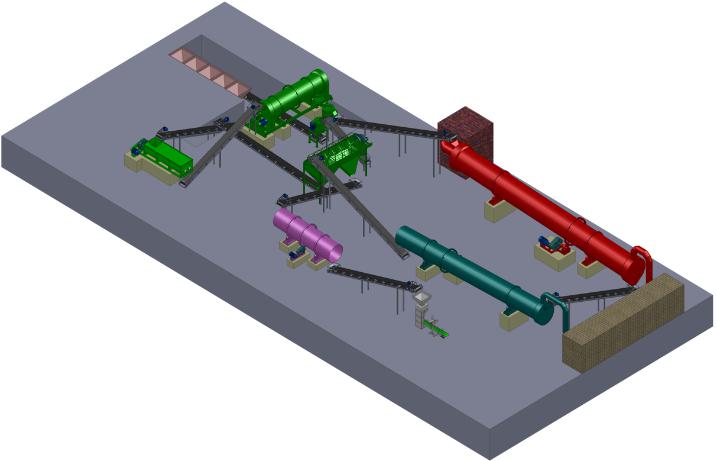

Re ka fana ka moralo oa ts'ebetso le phepelo ea mohala oa tlhahiso ea rotary drum granulation.

Mohala ona oa tlhahiso ea Rotary Drum Granulation o na le mochini o tsitsitseng oa ho kopanya, mochini o kopanyang habeli oa shaft, granulator ea drum ea rotary, crusher ea ketane, mochini o omisang meqomo oa rotary & cooler, mochini o hlahlobang meropa oa rotary le lisebelisoa tse ling tse thusang tsa manyolo.Sephetho sa selemo se ka ba lithane tse 30,000.Joaloka moetsi oa lihlahisoa tsa manyolo, re boetse re fa bareki lithapo tse ling tsa granulation tse nang le matla a fapaneng a tlhahiso, joalo ka 20,000 T/Y, 50,000T/Y, le 100,000T/Y, joalo-joalo.

Molemo:

1. E amohela granulator e tsoetseng pele ea rotary, sekhahla sa granulation se ka fihla ho 70%.

2. Likarolo tse ka sehloohong li amohela lisebelisoa tse sa senyeheng le tse thibelang ho bola, lisebelisoa li na le nako e telele ea tšebeletso.

3. Amohela poleiti ea polasetiki kapa lesela la tšepe le sa hloekang, lisebelisoa tse seng bonolo ho khomarela leboteng le ka hare la mochine.

4. Ts'ebetso e tsitsitseng, tlhokomelo e bonolo, ts'ebetso e phahameng, tšebeliso e tlaase ea matla.

5. Adopt lebanta conveyor ho hokahanya mohala kaofela, ho hlokomela tlhahiso e tsoelang pele.

6. Amohela lihlopha tse peli tsa kamore ea ho lokisa lerōle ho sebetsana le khase ea mohatla, e nang le botsoalle ba tikoloho.

7. Linako tse peli tsa ts'ebetso ea ho hlahloba li netefatsa li-granules tse tšoanelehang tse nang le boholo bo lekanang.

8. Ho kopanya ka ho lekana, ho omisa, ho pholile le ho roala, sehlahisoa se felileng se na le boleng bo phahameng.

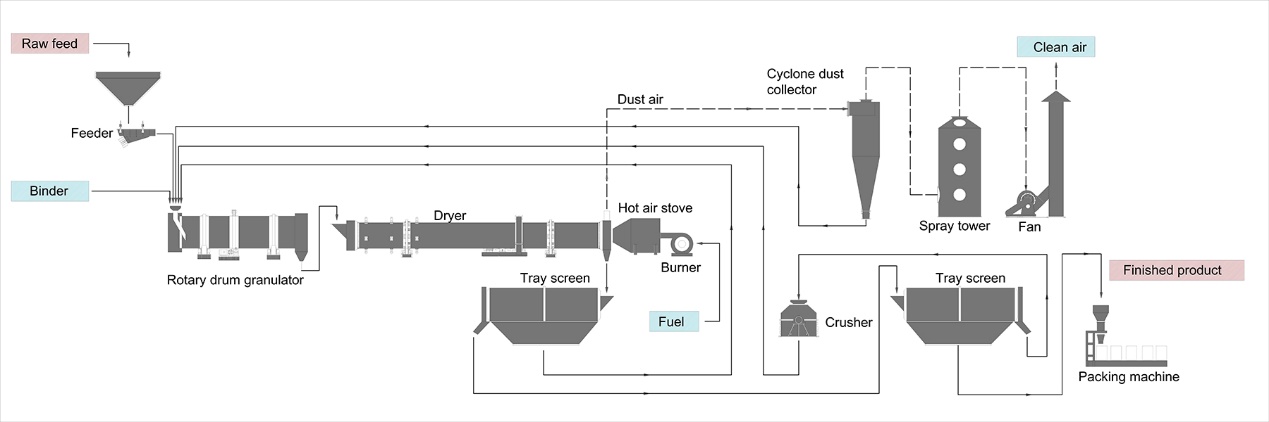

Phallo ea ts'ebetso:

Ho kopanya lisebelisoa tse tala (mochini o tsitsitseng oa ho kopanya)→ Ho kopanya (Motsoako oa shaft habeli)→ Granulating (rotary drum granulator) → Ho omisa (se omisa moropa) → Ho pholisa (moropa o pholileng oa rotary) → Sehlahisoa se felileng (mochini oa rotary o sefang meropa) → Boemo bo tlase ho silakanya li-granules (mochine o otlolohileng oa ketane ea manyolo) → Ho roala (mochini oa ho roala moqomo oa rotary) → Lihlahisoa tse felileng li paka (sephutheloana se ikemetseng) → Ho boloka (ho boloka sebakeng se phodileng le se omileng)

TSEBISO:Mohala ona oa tlhahiso ke oa litšupiso tsa hau feela.

1.Raw thepa batching

Ho latela tlhoko ea 'maraka le liphetho tsa mobu oa lehae, lisebelisoa tse tala tse kang urea, ammonium nitrate, ammonium chloride, ammonium sulphate, ammonium phosphate (monoammonium phosphate, diammonium phosphate, calcium e boima, calcium kakaretso) le potasiamo chloride (potassium sulphate) li tla abeloa. ka tekanyo e itseng.Li-additives le li-trace elements li lekanngoa ka tekanyo ea lebanta 'me li lekana le karolo e itseng.Ho ea ka karo-karolelano ea foromo, lisebelisoa tsohle tse tala li kopantsoe ka ho lekana ke motsoako.Mokhoa ona o bitsoa premix.E netefatsa ho hlophisoa ho nepahetseng le ho etsa hore batching e sebetse hantle le e tsoelang pele.

2.Ho kopanya

Kopanya ka botlalo lisebelisoa tse tala tse lokiselitsoeng 'me u li hlohlelletse ka mokhoa o ts'oanang, o behang motheo oa moiteli o sebetsang hantle le oa boleng bo holimo.Horizontal mixer kapa disc mixer e ka sebelisoa esita le ho kopanya.

3.Materials Granulating

Kamora ho pshatleha, lisebelisoa li isoa ka har'a granulator ea moqomo oa rotary ka conveyor ea lebanta.Ka ho potoloha ho sa khaotseng ha moropa, lisebelisoa li etsa bethe e bilikang, 'me e tsamaea ka tsela e itseng.Tlas'a matla a extrusion a hlahisoang, lisebelisoa li agglomerate ka likaroloana tse nyane, tse fetohang mantlha, li kopanya phofo ho pota-pota ho etsa li-granules tse tšoanelehang.

4.Ho omisa menontsha

Lisebelisoa li tla omisoa ka mor'a granulating ho fihlela boemo ba metsi.Ha se omisang se ntse se potoloha, letoto la mapheoana a ka hare a tla phahamisa thepa ka ho ala lebota le ka hare la se omisang.Ha thepa e fihla bophahamong bo itseng ho phutha mapheo a morao, e tla oela ka tlase ho se omisang, ebe e feta molapong oa khase e chesang ha e oela.Sistimi e ikemetseng ea ho hloea moea, ho kenya litšila ho tsoa bohareng ho fella ka matla le ho boloka litšenyehelo.

5.Ho Pholisa menontsha

Rotary drum cooler e tlosa metsi a manyolo 'me e theola mocheso, e sebelisoang ka mochini o omisitsoeng oa rotary ka manyolo a manyolo le tlhahiso ea manyolo, e eketsang lebelo la ho pholisa haholo, le ho imolla ho matlafala ha mosebetsi.Cooler ea rotary le eona e ka sebelisoa ho pholisa lisebelisoa tse ling tsa phofo le granular.

6. Ho hlahlojoa ha manyolo: Ka mor'a ho pholile, li-granules tsohle tse sa tšoaneleheng li hlahlojoa ka mochine oa rotary screening 'me li fetisetsoa ka lebanta la conveyor ho motsoako ebe li kopantsoe le lisebelisoa tse ling tse tala bakeng sa ho tsosolosa.Lihlahisoa tse feliloeng li tla isoa mochineng oa ho roala manyolo a kopantsoeng.

7. Ho roala: Ho sebelisoa haholo-holo ho roala holim'a li-quasi-granules ka filimi e sireletsang e ts'oanang e le hore e atlehe ho atolosa nako ea ho boloka le ho etsa hore li-granules li be bonolo.Kamora ho roala, mona ho tla ts'ebetsong ea ho qetela - ho paka.

8. Sistimi ea ho paka: Mochini oa ho paka o ikemetseng o amoheloa ts'ebetsong ena.Mochini o entsoe ka mochini o boima oa othomathiki le oa ho paka, sistimi e tsamaisang, mochini o tiisang joalo-joalo.Hopper e ka boela ea hlophisoa ho latela litlhoko tsa bareki.Ho paka ka bongata ba lisebelisoa tse ngata joalo ka manyolo a manyolo le manyolo a kopantsoeng ho 'nile ha sebelisoa haholo liindastering le masimong a fapaneng.

Nako ea poso: Sep-27-2020