E 'ngoe ea melemo e meholo ea ho sebetsa le Yi Zheng ke tsebo ea rona e felletseng ea sistimi;ha re litsebi feela karolong e le 'ngoe ea ts'ebetso, empa ho e-na le hoo, karolo e' ngoe le e 'ngoe.Sena se re lumella ho fa bareki ba rona pono e ikhethang ea hore na karolo ka 'ngoe ea ts'ebetso e tla sebetsa hammoho joang ka kakaretso.

Re ka fana ka litsamaiso tse felletseng tsa granulation, kapa lisebelisoa tsa motho ka mong bakeng sa lits'ebetso tsa inorganic le organic.

Re ka fana ka moralo oa ts'ebetso le phepelo ea mohala oa tlhahiso ea manyolo o sa omiseng o sa omiseng.Lisebelisoa li ne li kenyelletsa Hopper & Feeder, rola (Extrusion) Granulator, Rotary Screen, Bucket Elevator, Belt Conveyor, Packing Machine le Scrubber.

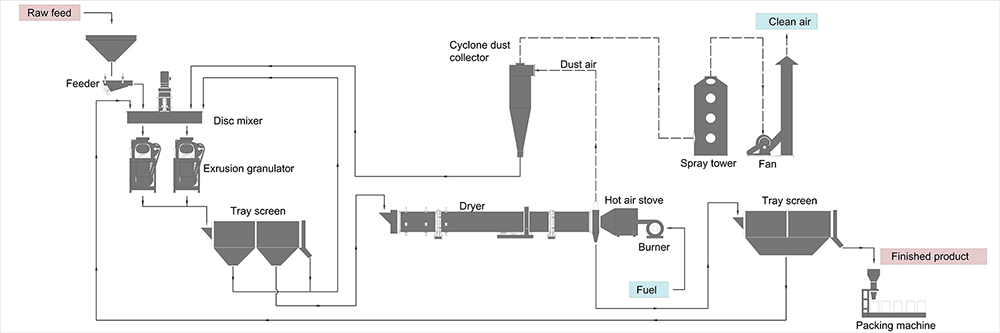

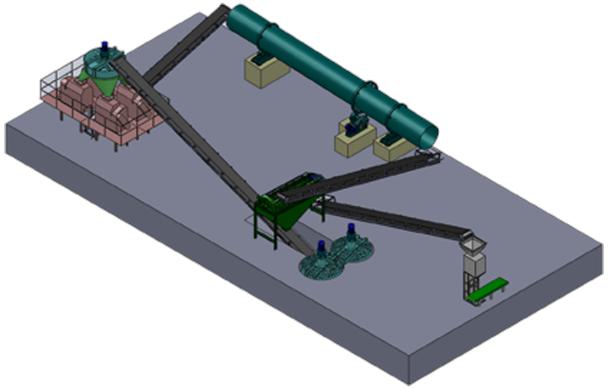

Sena Mohala oa tlhahiso ea granulator (Extrusion) o ka hlahisa manyolo a kopaneng a phahameng, a mahareng le a tlase bakeng sa lijalo tse fapaneng.Ka granulator e habeli ho hlahisa li-granules, mohala oa tlhahiso ha o hloke ts'ebetso ea ho omisa, ho ba le matsete a manyane le tšebeliso e tlase ea matla.Lirolara tsa khatiso tsa granulator li ka etsoa ho etsa libopeho tse fapaneng le boholo ba thepa.Mohala o kenyelletsa mochini o ikemelang oa ho roala mabanta, li-conveyors tsa mabanta, li-mixer tsa pan, li-pan feeder, li-granulator tsa extrusion, mochini o hlahlobang oa rotary, ntlo ea polokelo ea lihlahisoa tse felileng, le mochini o pakang o othomathike.Re itokiselitse ho fana ka lisebelisoa tse tšepahalang ka ho fetisisa tsa manyolo le tharollo e loketseng ka ho fetisisa bakeng sa bareki ba rona ba hlomphuoang.

Melemo:

1. Amohela khatello ea mochini ho theha li-granules, ha ho hlokahale ho futhumatsa kapa ho nosetsa lisebelisoa tse tala

2. E loketse lisebelisoa tse thibelang mocheso, tse kang ammonium bicarbonate

3. Ha ho na tlhoko ea ts'ebetso ea ho omisa, matsete a tlase, tšebeliso e tlase ea matla.

4.Ha ho na metsi a litšila kapa litšila tsa khase, ha ho na tšilafalo ea tikoloho.

5. Kabo ea boholo ba likaroloana tse tšoanang, ha ho na agglomeration.

6. Sebopeho sa Compact, theknoloji e tsoetseng pele, ts'ebetso e tsitsitseng, tlhokomelo e bonolo.

7. Ts'ebetso e bonolo, e bonolo ho elelloa ho laola ka mokhoa o itekanetseng, ho eketsa katleho ea tlhahiso.

8. Mefuta e mengata ea lisebelisoa tse tala, ha ho na tlhokahalo ea thepa e khethehileng

Process

1. Automatic Batching Machine

Taba ea pele, lisebelisoa tse fapaneng li lekantsoe ho latela foromo ka mochini oa batching oa li-bins tse 5, o ka tlatsang lisebelisoa ka boits'oaro ka nepo e phahameng le ts'ebetso e phahameng, ka hona boleng ba manyolo bo netefatsoa.Ka mor'a ho kopanya, lisebelisoa li fetisetsoa ho pan mixer.

2. Disc Mixer

Re nka lihlopha tse peli tsa li-disk mixer moleng ona oa tlhahiso ea manyolo.The cycloidal reducer e khanna shaft e kholo ho potoloha, 'me ka lehlakoreng le leng e khanna matsoho a ferekaneng.Ka ho tsukutleha ha matsoho a khathatsang le likharafu tse nyenyane holim'a tsona, lisebelisoa tse tala li kopane ka ho feletseng.Ka mor'a ho kopanya, lisebelisoa li lokolloa ho tloha ka ntle ho tlase.Lehlakore le ka hare la disc le amohela poleiti ea polypropylene kapa tšepe e sa hloekang, e etsang hore lisebelisoa li se ke tsa khomarela habonolo, le ho hanyetsa ho senya.

3. Mokelikeli oa Fertilizer oa Habeli o Habeli

Ka lebanta la conveyor, lisebelisoa tse tala tse tsoakiloeng hantle li fetisetsoa ho pan feeder, e fepang lisebelisoa ka mokhoa o lekanang ho li-granulator tse 'nè tsa extrusion tlas'a sefepi ka hopper.Ka li-roller tsa khatello e phahameng tse pota-potileng, lisebelisoa li fetisetsoa ka lilae.Lilae li phalla ho ea kamoreng e sithabetsang tlas'a mochine oa khatiso, moo li phunyeletsoeng ke li-roller tse senyang le ho hlahlojoa ho fumana granular e hlokahalang.Lirolara tsa khatiso li nka tšepe ea mofuta o mocha o hananang le kutu, ho senyeha le ho ba le tšusumetso.

4. Mochini oa ho hlahloba ka rotary

Ka lebanta la conveyor, li-granules tse tsoang ho extrusion granulator li romelloa mochining oa rotary screening, moo li-granules tse sa tšoaneleheng li fetang ka lesoba la skrineng ebe li tsoa ka sekoting se ka tlase, ebe li khutlisetsoa ho pan feeder, ha li-granules tse tšoanelehang li ntse li phalla. sehlahisoa se pheletsong e ka tlase ea mochini ebe se fetisetsoa ntlong ea polokelo ea lihlahisoa tse felileng.

5. Mochine oa ho Paka o Iketsetsang

Ka sebaka sa polokelo ea lihlahisoa tse feliloeng, li-granules tse tšoanelehang li lekanngoa le ho patoa ke mochini oa ho paka o ikemetseng.Yuniti e na le mochini oa ho bekha le ho paka o ikemetseng, sesebelisoa se fetisang, sesebelisoa sa ho tiisa le se fepa.E na le likarolo tsa ho nepahala ha boima bo phahameng, ts'ebetso e tsitsitseng, tšebeliso e tlaase ea matla, le ho lula fatše ho fokolang.

Nako ea poso: Sep-27-2020